11 Types of Pallets to Easily Transport Materials & Goods

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

If you have any experience with warehouse or distribution management, you probably encountered various types of pallets at different points of your work life. The main objective of using pallets is to transport and store goods while maintaining health and safety standards.

To untrained eyes, all pallets might appear almost idenftical, featuring some jointed metal plates or wooden boards.

But an expert surely knows that pallets vary largely in their designs as well as raw materials, and each of them is suitable for specific tasks. For example, you can use plastic or wood pallets for transporting food and beverages.

Yet, when it comes to shipping construction materials, you can't think of anything else other than metal pallets. Let's explore the world of pallets so that you have all the necessary info under your sleeves to choose the appropriate design, material, and feature for your needs.

7 Types of Pallets by Design

Every pallet has a longitudinal base and a horizontal deck on top of the base. Pallets mostly differ in the design and size of these two parts to carry all types of warehouse products during storage or in shipping in big truck types of trailers. Here are the most common designs of pallets with their features and advantages.

Stringer Pallets

This type of pallet is extensively used all over the United States. Stringer pallets have a top and a bottom deck to provide better support for unit loads.

Typically, there are 3 slabs or boards placed longitudinally in between the top and bottom platforms. The longitudinal boards are called stringers, and they provide adequate stability to the decks.

The Grocery Manufacturer Association or GMA (now called the Consumer Brands Association) standard size is 48" x 40" for the top and bottom decks so that they can carry 4600 pounds of maximum weight. Although the stringers are normally 2' x 4's in size, you can customize the pallet measurements according to your needs.

Stringer pallet types can be your go-to option to ship unit loads, store your goods at a raised position, and haul them from storage to cargo. As per the entry angles, stringer pallets can be divided into two categories:

Two-Way Stringers - Most stringer pallet styles only support two-way entry, and hence, the maneuvering machinery like forklift trucks or pallet jacks can access and lift the pallet from two sides. Although two-way pallets are a bit difficult to maneuver, they offer better strength and weight capacity.

Four-Way Stringers - When the stringers of a pallet have two or more notches on each side, a forklift can access the tool from 4 angles. This way, four-way stringers offer more convenience. However, the notches sometimes reduce the overall weight capacity of the pallet.

Block Pallets

For faster and better transporting, block pallets consist of 9 to 12 columnar blocks or posts instead of extended boards. The block design allows the forklift or front loader to enter from all four sides.

Generally, the block panels have only the top deck, which gives them the name 'Skid.' The pallet may also have a bottom deck for better support, yet the blocks mainly strengthen the top deck as it carries the unit loads. These types of pallets also have a GMA standard 48" x 40" size, and it can carry up to 5500 pounds.

As you can judge from the numbers, block pallets of the same size have a higher weight capacity compared to string pallets. If you're shipping or storing heavier loads, you can rely on block pallets for extra stability and rigidity.

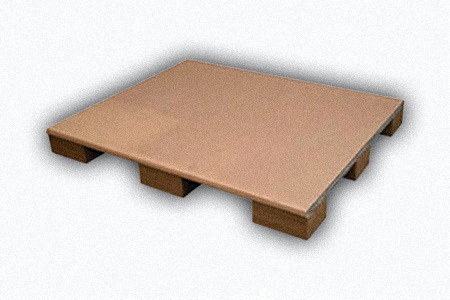

Solid Deck Pallets

The top deck of this type is made from a broad continuous sheet with no gaps or spaces. We use solid deck pallets to carry and store the small items that tend to get misplaced or lost through the gaps of other different pallet types. The base can be made of stringers or blocks according to your requirements.

You can easily make DIY solid deck pallets with the lowest effort. The affordable price is the main advantage of these pallets. Also, they are a great option to maintain hygiene as you can clean them very easily without concerning about the hard-to-reach corners.

If you decide to repair a solid deck pallet, you'll want to use standard types of drills and types of drill bits, rather than a hammer and nails like you would with stringer pallets. In this case you'll be using whatever types of screws you have on hand.

Double Face Pallets

As you already know, some pallets have two decks on each side of the stringers or blocks. These pallet types are known as a double-face pallet, and they are widely used for ensuring stability and durability.

While the top deck alone is enough to carry the load, an extra bottom deck distributes the overall weight of the products more evenly, eliminating the chances of collapse and damage during transportation.

You can use the double-face types of pallets for carrying heavy products that demand resilience and strength. Double-face pallets fall into two categories:

Reversible Pallets - When the two decks or faces are identical in size and design, the pallet is reversible, and you can load products on either side of the pallet.

Non-Reversible Pallets - In this type, the top and bottom sides are dissimilar in size, and only the top side is qualified for stacking goods.

Winged Pallets

Typically, the stringers of any pallet are in complete alignment with the boards or sheets of the decks. Winged pallets are different as they have extended decks that hang over the blocks or stringers. This way, the stringers are placed more towards the middle for increased weight capacity.

Also, the decks offer an additional surface area for holding a large number of products. If you want to transport oversized, bulky products in a large number, winged pallets will be an ideal choice. There are two types of winged pallets:

Single-Winged Pallet - If the top deck board is extended and the bottom one is in regular size, the pallet is called single-winged.

Double-Winged Pallet - In this type, both the top and bottom deck are extended for holding extra weight.

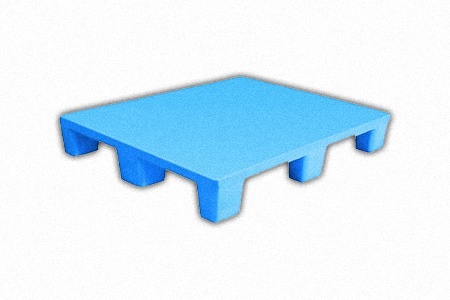

Roto-Molded Pallets

Roto-molded pallets are constructed from one solid piece of plastic, reducing the number of crevices and increasing their ability to be cleaned. In any industry where cleanliness and hygiene are a top priority, you'll find these being used.

They can carry heavy loads and their strength can be increased by forming the plastic around steel frames, which will hide in the inside like a skeleton. These pallet styles are substantially more expensive than your more basic wood pallet options.

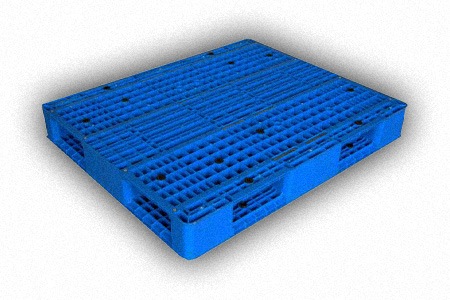

Injection Molded Pallets

Plastic injection is a wonderful technology that has afforded us advanced types of pallets that can even be color coded. These are made cheaper by having greater air space in them which doesn't effect the durability and strength by much at all.

This does make them more difficult to clean. You'd hose these down and hope for the best. Whether you're using jacks, forklifts, or loaders, these pallets can go a long way at your warehouse, saving effort and money in the long run.

4 Types of Pallets by Construction Material

Over the years, different materials have been used to construct pallets. While some have failed to offer the required stability, some have cemented their position on the marketplace with their quality, strength, durability, and affordability.

Among all types of pallet materials, we have listed the best and most common ones below:

Wood Pallets

When we think of pallets, wood-made pallets cross our minds instantly. That's because wood is the top-tier material that’s extensively used for making pallets everywhere in the world.

Pallets made from oak or pine wood are readily available in supply stores. Wood pallets are affordable and capable of carrying medium to heavy loads. As long as you store them in dry areas, wood pallets can last for decades without any fancy maintenance.

Wooden surface offers higher friction levels so that your products don't slip while transporting. The material is mainly famous because it's repairable and recyclable without any need for melting chemicals. All you need is your basic types of hammers and types of nails and you're back in business. You can often reuse the same exact nails, too, even if you have to hammer them flat..

If any board or stringer breaks, you'll be able to fix it instead of replacing it entirely. However, wood pallet types have many severe drawbacks too.

The material is susceptible to moisture and bacterial or insect attack. Once the wood is wet, it loses effectiveness and begins to rot and decay. So, you have to ensure a moisture-free area if you want to store your products on wooden pallets.

You'll find both soft wood pallets and hard wood pallets. Soft wood is the cheapest and they're often considered consumable after one or two uses. Instead of throwing them away, learn how to build a pallet adirondack chair instead.

Hard wood pallets are sturdier and and often used in warehouses to move materials around over and over in that one location, rather than being lifted into a shipping truck and transported across the country.

You can also find presswood pallets, made of fibers similar to another option which are plywood pallets. Both types of pallets have the benefit of reducing cost and being plenty of sturdy when ran across blocks, stringers, and deckboards.

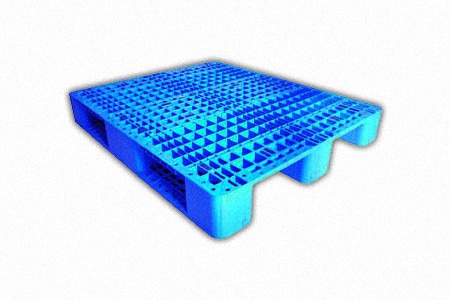

Plastic Pallets

Plastic pallets have become a popular choice for carrying lightweight to medium-heavy goods like food, pharmaceuticals, beverages, etc.

These pallets are made from polymeric plastic substances like polyethylene. Also, plastic is reusable and can be made from recycled pallets, bottles, and other HDPE materials.

You can count on plastic pallets for durability and maximum safety. The material is resistant to weather, insects, and microbial attacks. It's lightweight, easy to clean, and doesn't contaminate with chemicals.

If you want to use your pallets for decades, opt for the plastic ones. The only drawback of plastic material is that it's costlier than many other materials on the list.

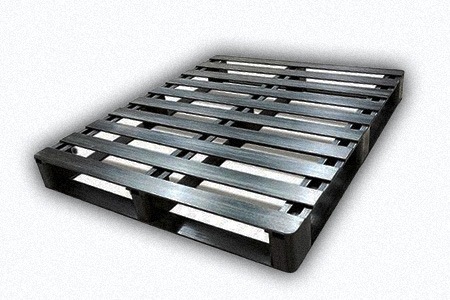

Metal Pallets

When you need extra strength for transporting the heaviest materials, metal pallets are the way to go. Only some particular industries use metal pallets for shipping automotive products, construction, and military equipment.

Metal pallets are constructed from carbon steel, aluminum, or stainless steel. As you can guess, these pallets are highly durable and super strong.

Metal is also resistant to weather changes, moisture, chemicals, and microbes. This way, they are suitable for both shipping and storing.

However, metal pallet types are the heaviest of all, and that increases the transportation cost. Also, some metals are vulnerable to rust and corrosion. Nowadays, you can purchase galvanized steel-made pallets as they are rust-resistant and fireproof.

Paper Pallets

Paper is the most cost-effective and environment-friendly material of all. These types of pallets are made from cardboard, recycled paper, or corrugated sheets.

It's lightweight, customizable, and easy to carry. Paper pallets are used to transport light products like food, shoes, beverage, and even furniture.

As the paper is resistant to microbial attacks and chemical contamination, you can use them to store lightweight goods. There are also some downsides to paper pallets. For instance, they get ruined while in contact with water. Also, they will ignite quickly if there is any fire emergency.

Types of Pallets to Handle Your Shipments & Materials

So, we have talked about different kinds of pallets that you can use to pile up, assemble, and transport your products. If you want something cost-effective and durable, you can choose wooden or plastic block pallet styles.

As the materials are stable and reusable, you don't have to worry about the replacement costs for years. Follow our guide and keep quality and safety in mind while picking to end up with the finest types of pallets of the marketplace.