10 Types of Springs & Their Specific Design Uses

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

Almost anything that contains some mechanism around you has at least one of the types of springs – from small consumer products such as TV remotes to larger items such as cars to industrial machines in factories.

Spring is a mechanical device that stores energy and uses it to push, pull, support, protect, or lift. There are many kinds of springs available in the market, and they vary depending on the torque required for different uses.

Today, I will discuss some of the most useful and common kinds of springs with you so you'll be aware of what's available. Without any further ado, let's jump right in.

10 Types of Springs

Here are the most common types of springs and their uses. There may be weird, random, and rare spring types out there but let's stick to what's useful instead of deeply specialized. Use Hooke's Law to calculate spring tension and then you can figure out exactly which spring you need below.

Compression Spring

They are the most common type of springs available. When we think of springs, we think of these. These springs are coiled helically, which is the most common design of springs we see.

Compressions springs are made to give an opposing force if they are pressed. Essentially, they resist external forces applied linearly. You've seen them box springs and some box spring alternatives.

Commonly they are found in spring types of mattresses, shock absorbers, retractable pens, mechanical pencils, suspension systems, remotes, etc. Generally, these springs are open-ended and coiled at the same diameter.

But varied diameter compression springs exist too, such as hourglass-shaped, conical, barrel-shaped, etc. There's also the widely used die springs which are a type of compression spring known for their long life and consistency over time.

As stated, compression springs are used in applications where springs are needed to resist force or store static energy. They can work independently, but you will also find them fitted in a hole or over a guiding rod.

Tension Spring / Extension Spring

Called by both of the above names, extension springs look similar to compression springs. They, too, are coiled helically, and their coils are much tighter in comparison.

When relaxed, there is no gap at all between the coils of an extension spring. That is because they are meant to be pulled, not compressed.

The purpose of extension springs is to oppose the force and provide tensile load when an external force pulls its sides. These springs are loaded in tension and get stretched if a force is applied.

Trampolines are a common application of tension springs. When you jump on one, the tension types of springs get extended under your load. This is part of why it's best to be careful what you put under the trampoline. Anything interfering with these springs while under tension is dangerous.

The springs then release the energy they store from this, propelling you up in the air. Other common uses include garage doors, luggage scales, weight machines, levers, etc.

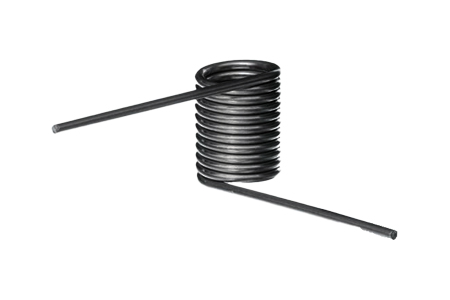

Torsion Spring

Torsion springs are also slightly similar to the previous two springs, differing in the direction they exert energy. These springs are coiled helically, too.

Force applies to torsion springs in a radial direction, against which the spring uses torque or a twisting force. Typically, these springs are placed over a shaft, with their legs fastened on two plates.

When an external force squeezes the plates, they put a force on the spring radially, which then exerts energy outwards following the opposite direction of the applied force.

This entire process happens in less than 360-degree rotation. The job of a torsion spring is to hold a system in a fixed place at a fixed angle, so if the system is moved, the spring brings it back to the original state (or as close to it as possible).

Typical uses of torsion springs include clothespins and similar types of clamps, mouse traps, hair claw clips, clipboards, door hinges, automobile starters, etc.

Belleville Springs

Also called the coned disc spring or conical spring, Belleville springs are disc-shaped. The disc is slightly tapered, giving them a conical look. They are usually loaded either statically or dynamically to an axis.

These types of springs are used to help fasteners. For using them, fasteners such as blots are needed, which are inserted in the spring to pre-tension the spring.

The bolt is also used to attach the spring to a surface. You can also nest these springs for higher load capacity or higher deflection.

A unique characteristic of these springs is that they need less room for installation but still manage to bear a large amount of energy or load. Because of this, common uses of Belleville springs include high-pressure valves, shock absorbers for drill bits, slip and overload clutches, etc.

Clocks or Constant Force Springs

These springs are primarily found in various types of clocks and clockwork, so they are also called clocks springs. They also go by the name spiral spring.

As suggested by the name, the objective of constant force springs is to constantly release a fixed amount of rotational energy without any breaks.

Constant force springs look like a roll of tape, made of steel bands that have been tightly wound like a roll. The number of rotations on these springs is lower than usual springs.

The purpose of these springs is to counterbalance applications, keeping the mechanism moving. They are used in mechanisms that require constant rotation while also exerting the same amount of energy.

Other than clocks, you will also find them as height adjusters for monitors, wind-up toys, automotive seat recliners, DC motors, and window regulators.

Leaf Springs

It is one of the earliest types of springs. Also known as cart spring and semi-elliptical spring, these springs aren't helical or spiral.

Rectangular metal sheets, called leaves, are sandwiched on each other to make a leaf spring. This sandwich formation creates a slender, long, arc-shaped spring.

The everyday use of leaf springs is for vehicle suspensions for wheels. In the most popular configuration, the wheel's axle sits at the center of the spring's arc.

For heavy vehicles such as trucks, more layers of leaves are stacked to give better support. Leaf springs provide damping and springing to a vehicle. They also act as the linkage to hold the axle of the wheel in position.

Drawbar Springs

Combine the functionality of an extension spring with the design of a compression spring – and you get a drawbar spring. In these springs, coiled compression springs are combined with U-shaped wires inside.

These springs are applicable in situations where you need the limiting feature of a compression spring and the tension of an extension spring. This is mainly required for safety reasons in situations where a sprung failure would cause an accident.

Under a load, the mainspring compresses, and the drawbars get extended. If a regular spring undergoes continuous deflections, it will eventually get deformed and cause spring failure.

The drawbar design stops that from happening with the self-limiting feature. Typical uses of drawbar springs include swing sets, pool covers, boat tethering, tensioning gates, etc.

Garter Springs

Take an exertion spring and join its ends to form a rounded spring – that would be a garter spring. They are used to give a radial force in a mechanism with variable loads.

When an outside load is exerted on it, it contracts its energy to go back to the original diameter. You can find two types of garter springs – compression garter spring and exertion garter spring.

The former exerts radial forces in the outward direction (away from the center), while the latter does so in the inward direction (towards the center).

Typical uses of garter springs include radial, pneumatic, and hydraulic shaft seals, oil seals, belt-driven motors, and conveyor systems.

They can withstand pressure from all directions and maintain their own pressure inside a cylinder or over it, which is why the first two uses are the most popular for garter springs.

Volute Springs

Also called conical springs, volute springs are compression springs made from flat metal strips and have a conical shape. These are interesting types of springs that will captivate you when you first get your hands on one.

They are used in applications that need a compression spring with a long fatigue life. The thickness of the metal plates varies from 1 – 32 millimeters.

Under pressure, the flat coils slide past each other, which enables the spring to take a very short length. This length is shorter than you would get from a typical helical spring with the same dimensions.

Because of how the spring looks when compressed, these springs have another fun name, bamboo spring. The spring creates a v shape, with the outermost coil being the shortest and the inner layers being longer as you go through more layers.

There are two types of volute springs – one with the v shape on one end and the other with the v shape on both ends. The latter is called a double volute spring.

These springs are excellent at absorbing relatively more energy than their occupied volume and space and producing a large load.

Typical uses of volute springs include shock absorbers, garden pruning shears, tank suspension systems, buffering devices, etc.

Other Types of Springs

There are other spring types that aren't really traditional types of springs, such as hydraulic springs that use fluid, air springs and gas springs that use pressurized gases, among others.

There's box springs in mattress alternatives and mattress supports, but those are really just an array of standard springs.

These don't quite fit the bill but they are called springs in various industries so I mention them just in case.

The Types of Springs & Their Uses

So, that was all the different spring types I wanted to share with you today. We hope you learned something new about these handy little (or big) devices.

Now you should understand that different types of springs are found virtually everywhere – and they deserve more credit than we give them.

You'll Also Enjoy:

- 12 Types of Tile: All the Different Varieties to Choose From

- 30 Types of Arches, Modern & Historical, Visually Displayed

- 7 Bed Skirt Alternatives to Escape the Annoyance & Look Nicer

- 12 Types of Ladders to Efficiently & Safely Get the Work Done

- 15 Types of Staircases to Fit Your Decor Style Perfectly