How to Remove a Stripped Bolt (& How to Avoid Causing Them)

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

There are a number of ways that a bolt can become stripped, rounded, seized, and seemingly impossible to remove. Whether you’ve having issues with a screw, a bolt, or something similar - here are a variety of solutions that you can try.

I’m confident that if you try everything mentioned on this page until something works, that you’ll find the solution you need. If none of these ideas can get it done, you may just be out of luck, or you may need to enlist the help of a professional.

Chances are that one of the strategies I’m about to outline will work in your favor. Let me know how it goes! In any case, let’s start by discussing what causes bolts and screws to become stripped in the first place.

Obviously, if you’re already looking for help, it’s kind of late for preventative measures but having an understanding of how and why this happened is still useful to know not only for the future, but for solving today’s puzzle, too.

What Causes Stripped Bolts & Screws?

Here's the 5 most common stripped bolt causes, along with screws. Avoiding these is key but they also give insight into the fixes, so please skim them at least.

Wrong Bit Size for Screws

When it comes to screws, a common way to strip them is by using the incorrect tool, for instance using a screwdriver or a drill with a head that’s too small for the screw. Uneven application of pressure from the bit can cause a screw to strip too. It's a big cause of stripped allen screws due to the small size of the wrenches.

This causes excess pressure towards the center of the screw head, where it’s not as strong, and the metal starts to bend and break. This first cause can be avoided by simply ensuring that you’re using the right size bit to manipulate your screw.

Over-Tightening a Bolt

When it comes to a bolt, the most common way to strip it is by over-tightening it. A screw is a lot easier to deal with than a bolt that’s stuck. Overtightening the bolt weakens the metal, and the whole head of the bolt can snap clean off, then you’re in real trouble.

Manufacturing Defect or Low Quality Materials

In both cases, while user error can be a prominent cause, it can also be a manufacturing defect or simply the result of using low quality parts. Even cheaper screws and cheap types of bolts should, in theory, be able to stand up to normal everyday use - but you never know with some of the junk that people out there are trying to sell us.

A lower quality part combined with age, weather conditions, and even the slightest bit of user-error (or even used under perfect conditions) can eventually break on you, and you’ll find yourself here looking for the answer.

Mismatching Material Grades

Using different materials and grades for the bolt and for the fastener can also cause problems.

For example, some fasteners have a galvanized layer to protect them, but this layer adds extra size, which means your bolt or screw won’t fit perfectly, the fit will be too tight and this can cause it to seize and get stuck.

If you’re using something with an extra seal, don’t put it into just any hole - use one that’s meant to accommodate it. Also, consider if you need to remove rust from the screw or bolt heads.

Plain Old User Error

It’s often a case of user-error in one way or another. When things seem simple, like finding a screwdriver that fits into the head of a screw, those are the times where people might lean too heavily on common sense rather than truly knowing what to do.

Common sense would tell you that if the screwdriver fits in the screw, go for it - but in reality, it needs to be a perfect fit, not just “it fits”.

How To Remove a Bolt With a Stripped Head

Removing a bolt with a stripped head can be tricky. There are a few things you can try, depending on how severe it is. The head likely became stripped in the first place due to trying to remove it with an improperly-fitting tool. Having a socket that fits isn’t good enough, it needs to fit snugly in order to prevent stripping.

The first thing to do is apply some penetrating oil to help lubricate the bolt, even if this isn’t the main reason it’s stuck, it can still help loosen things up a bit so that the following strategies will work better.

Next, you can take a small file and file a line across the top of the head of the bolt, which could then be used to unscrew it. Another option is to hammer the end of one of the smaller cold types of chisels into the bolt with a few good whacks, then twist the cold chisel to remove the bolt.

Locking pliers can give you a better grip on the bolt head if it’s not too rounded. This can be a bit risky, since holding them and twisting at even a slight angle can drastically increase the chances of the bolt head snapping right off, so be very careful with this.

How to Remove a Bolt with Stripped Threads

If all else fails, you can try a screw extractor tool, too. There are bits you can put into most standard power types of drills, and use them to drill into the head of the bolt to extract it. Of course, you’ll want to try this before the head has fallen off, so once again, be careful with other methods and don’t be shy with the oil.

How to Get a Stripped Screw Out

The head of a screw and a bolt’s head are quite different, so if it’s a stripped screw you’re dealing with, there are some different things you can try. Screws can become stripped quite easily, and again, the biggest culprit is using a screwdriver that doesn’t fit perfectly.

With so many different sizes of screwdrivers, and so many of them that “kind of” fit into any given screw, it’s no wonder this happens so often.

The metal in screws can be on the softer side sometimes, too, which is fine as long as you’re using the right tools - but again - the downside here is emphasized by the wrong tools.

It’s an easy mistake to make in a lot of cases, for example a Philips head looks pretty similar to a Pozidriv bit but they aren’t the same, let alone a #2 Philips versus a #1 or #3. Just because it fits, that doesn’t mean it’s the correct tool!

The rubber band trick is the first thing you should try for a screw. Simply put a strip of rubber band in between the screw head and the screwdriver, so that your screwdriver is pushing down on the rubber band and into the head.

This can help fill in some of the gaps that were created in between the tip of the screw-driver and the head.

Using a file or a saw or whatever you can to cut a line across the top of the screw head (similar to the advice given for a bolt) is another good option. You’re essentially digging into the head of the screw to forcefully turn it into a slotted screw.

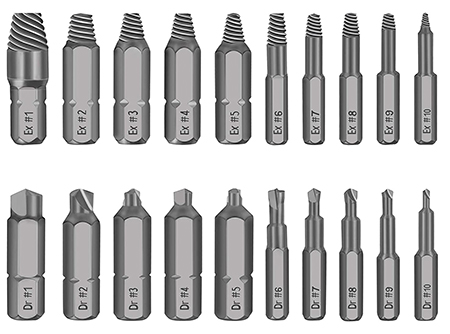

Drilling into the screw is another option, and again, there are a number of products that can help you with this that are designed for this exact task. What you’re looking for is called a screw extractor, and you should be able to find it at most hardware stores, and readily available for order online.

Final Thoughts on Removing a Stripped Bolt

Hopefully, you’ll now have a better idea how to remove a bolt with a stripped threads, or a stripped screw head, or any of the other causes of a bolt or a screw that just won’t come out.

It’s so satisfying when it finally comes loose and you’ve got it out of the way. Also, I hope that this information will help you understand why this happens in the first place, and how to avoid it happening in the future.

There are products that can help with this, but you can also use common household items (like the rubber band trick.) At the risk of sounding like a broken record, your main concern here should be not further damaging the bolt or screw. Be careful not to rip the head off, be careful not to strip it even further.

Understand which of these methods are lower-risk, which ones are higher-risk, and start with the lower risk ones (again, the rubber band trick won’t cause any additional damage, so it’s a great place to start.) You could also use a rubber band on the head of a bolt that’s started to become rounded by wrapping it around for extra grip.

Don’t let obstacles like this slow down your progress on whatever you’re working on, and avoid getting frustrated, first and foremost.

There have been times where I’ve gotten frustrated, used a little too much force, and broke the head right off instead of being calm and patient. Knowing how to remove a stripped bolt is part of the battle, and not letting it get that way in the first place is the other part.

If there’s one thing I’ve learned about doing work around the home, it’s that there’s always more to learn, and it’s usually a good idea to do a touch of research before using any tools on a project, even if it’s something like how to remove a stripped bolt, or how to avoid stripping bolts in the first place.