26 Types of Clamps & Their Uses in All Project Sizes [Pics]

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

There are types of clamps for every rhyme, every reason, every purpose, every season—we kid you not. For something that’s supposed to achieve a purpose as simple as holding two things together, clamps can be incredibly complicated.

Clamps are extremely versatile and are an integral part of toolkits around the world. Though they’re essentially holding two things together, the type of clamp a particular situation demands depends on the materials being held together.

26 Types of Clamps

While it’s a little bit of a Herculean task to make an exhaustive list of all the clamp types out there, here’s the next best thing — we cover all the main clamp styles and more right here.

Hand Screw Clamps

Also known as ‘toolmaker’s clamps’, these are most commonly used when there’s metalwork in the picture. Their adjustable jaws let them fit easily around any material and hold even angled objects quite firmly.

This makes them excellent options for furniture repairs. Additionally, the all-steel build makes them super durable and long lasting, though lately, wooden versions are also hitting the market.

Pipe Clamps

Extremely similar to sash clamps, pipe clamps are also called gluing clamps and are extremely versatile and easy to use. Where sash clamps have a long, flat bar, pipe clamps have round shafts and the clamp’s length is determined by the length of the pipe.

Pipe clamps have adjustable jaws and are very easy to move from position to position. The clamp’s length can also be increased by adding in more of the tube and very inexpensively.

Sash Clamps

Sash clamps are used for keeping large objects in place, such as cabinets, tabletops, doors, sash windows, and the like. They have long, heavy, flat bars with a jaw that can be adjusted with a screw.

Sash clamps also have sliding jaws that you can move along the clamp’s length and then lock into position to hold objects firmly. Though they’re quite strong and big, you’ll need to use more than one for a firm enough grip on the objects.

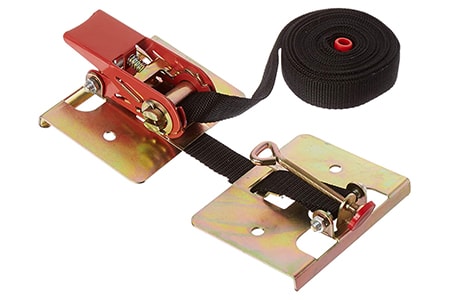

Web Clamps

Web clamps feature nylon bands that wrap firmly yet gently around objects to secure them. These types of clamps work extremely well on frames, keeping them securely in place sans any damage, thanks to the nylon.

The strings can be tightened, as necessary, with ratchets. Web clamps can be used with or without corner gripping pieces, ensuring that the pressure is evenly distributed, further preventing any damage to the object.

Spring Clamps

Among the most commonly-used clamps, spring clamps are used for various reasons and purposes. These clamps designs are available in a range of sizes and can be used for anything from beading and jewelry projects to woodwork.

The handles on these are generally PVC covered, ensuring that your skin is protected while working and most often, come with removable PVC covers for their tips, too (these can be removed while soldering).

The clamp’s tension springs (one of the many types of springs) also make it hard to open these clamps, ensuring that items are held in an extremely tight grip once the clamps are shut.

Bench Clamps

As the name suggests, bench clamps are meant to keep an item, atop a bench, firmly held in position. Instead of its own jaw, the bench clamp is designed in such a way that it uses the bench itself as the fixed jaw.

Bench clamps are used in carpentry, welding, and furniture making and are quite inexpensive, too. My brother has about 20 of them and we used them in our how to make a cutting board article.

Bench Vises

Bench vises feature both parallel and fixed jaws, both adjustable with a screw. These different types of clamps are generally used to keep objects in place, letting you work, sand, saw, or drill without worrying about the piece moving or shifting.

Some bench vises are even portable and can be clamped or screwed onto workbenches. For smaller ones, I absolutely recommend the portable type out of pure convenience. You'd think it wouldn't be this involved but you should consider vice clamp safety, too.

Quick-Action Clamps

Quick-action clamps are designed to be easily openable even with just one hand—this makes them the perfect combination of strong and powerful yet easy enough to use without any hassles.

The release on these clamps is light enough to be pulled with just a finger. Quick-action clamps feature a design similar to sealant guns, which is why many folks associate the two. I used several of these when I was learning how to build a pallet adirondack chair.

Hose Clamp

Sometimes called a hose fitting, these are wrapped around hoses at the ends and tightened down in order to secure the hose to a spout, nozzle, or pipe. The goal is to keep the hose in place and to prevent leaking.

Some types of hose clamps feature handles you can crank but many are tightened manually and then finished off with a screwdriver, acting like a turnbuckle of sorts.

Miter Clamps

Miter clamps hold together pieces with mitered ends together, at a right angle. These clamps generally have types of screws that fit underneath the frame of the object they’re holding down, while a bit clamps down onto the frame.

Miter clamps can be quite basic or advanced, with movable jaws and hard bodies—however, there’s no difference when it comes to the efficiency of getting the job done right.

Quick-Grip Clamps

Quick-grip clamps, as the name suggests, quickly grip objects using just one hand. The pressure is adjustable, which increases the versatility that these clamps bring to the table.

These clamps are especially great for thin materials or objects, as the jaws don’t close squarely. Therefore, these clamps are best avoided when thicker items are involved in the project.

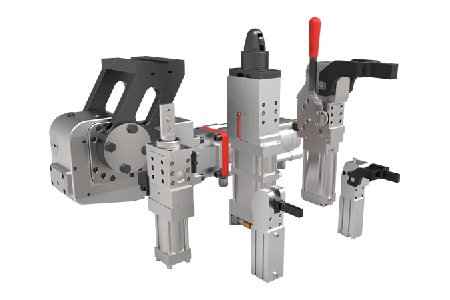

Pneumatic Power Clamps

As the name suggests, pneumatic power clamps are very strong. They combine force and power while still being user friendly and light. These are used in welding but also have light-duty variations for other applications.

These can pivot, tip, dump, or rotate parts. They also come in attachments that can continue to extend and give you more options and reach.

Marmon Clamp

Like a hose clamp, the marmon clamp is another type of band clamp, perhaps with a more heavy duty flange. It helps you connect two pipes are hoses together at their ends.

Sometimes called a ring clamp or marman ring, the tension is increased by tightening the bolt and nuts on the strap. Be careful not to over-tighten or you'll have to consult our how to remove a stripped bolt article.

Drill Press Clamps

Drill press clamps are designed for the drill press table, specifically to secure boards and materials to the table. This results in clean, accurate holes every time these types of drills are used.

Drill press clamps feature a quick release that lets them easily latch onto objects and release just as quickly. The tension is easily adjustable, too. Using a drill press clamp with a drill press keeps things precise and safe no matter what types of drill bits you're using.

Trigger Clamps

Trigger clamps are easy to operate with just one hand and use a trigger to adjust the clamp’s jaws and head. These types of clamps are extremely versatile and strong and while they’re generally commonplace in workshops, they’re also ideal for home and garden use.

Screw Clamps

Screw clamps are extremely strong and offer high levels of stability—this makes them very similar to power clamps, with the difference lying in the way that both types of clamps are operated.

Additionally, unlike power clamps that swiftly open and close in one motion, screw clamps feature a handle and thread that need to be screwed. The purpose of the thread is to speed things up as much as possible while the clamp is in use (though the screwing itself can take a bit of time).

G or C Clamps

People think these are called C-clamps or G-clamps due to the shape of it plus the screwing part (that forms the G), but the truth is the name comes from them originally being called "carriage maker's clamps" and eventually "carriage clamps".

They work exactly how they look like they do. Their construction is so incredibly durable that you can pass them on to your children and so forth for probably two or three generations at least.

Sliding, Bar, or F Clamps

Bar clamps are typically long, though the length may vary from clamp to clamp. The length of the clamp allows users to keep large projects stable and in place without breaking a sweat.

The project can be easily placed on the bar’s flat surface, allowing for the clamp’s head to easily slide up to hold the project securely and tightly. These clamp designs are available in a range of styles but are extremely integral to large projects, regardless of the type.

Cardellini Clamps

Cardellini clamps are generally used with tubing, with jaws that securely clamp onto these. These clamp styles are designed to be extremely versatile and can be used on round, square, or rectangular tubing without any hassles.

Cardellini clamps can also be used to grip equipment, clamp flat options, or even mount lights in a theater. Another similar option are barbell clamps.

Additionally, where most clamp types can get easily damaged if tightened too much, these are designed in a way that their jaws’ edges will press against each other when in use, which means that they are even more prone to getting damaged.

Therefore, care and caution need to be exercised when these are used, especially while adjusting or tightening.

Speed Clamps

Speed clamps are great. They can quickly be moved into an "almost tight" position and then hand-pumped into full tightness. There is one stationary side of the clamp with a long bar on it that the part with the hand grip slides along.

With the quickness of the gliding and then the ratcheting of the hand grip, the convenience of these can't be over stated. They come in various lengths so they can be used in nearly any project. Every garage should have a few of these.

Flooring Clamps

Flooring clamps are single-purpose, meant to be used when floors are being installed. They help hold the groove boards and tongue in place, letting the carpenter nail them down securely.

They can clamp down around 10 boards at once but have to be used in conjunction with other flooring clamps to work in this way. But it definitely saves time if you have more of them on hand.

Speed clamps have serrated, long metal bars that keep the adjustable head in place, when it’s clamped against an item or object.

As the head of the clamp is clamped down, the resulting pressure causes the serrated edges to lock. This, in turn, keeps the sliding head secure and prevents it from slipping, while in use.

Kant-Twist Clamps

Kant-twist clamps are multi-purpose clamps that are a combination of the efficiency of C-clamps and parallel clamps.

Owing to their free-floating jaws, these can easily adjust to non-parallel surfaces and won’t shift from the center even if pressure is applied to the jaw. Kant-Twist clamps are easy to use and allow a lot of movement.

Gripe Clamps

Gripe clamps are extremely simple designs that are mainly used while building clinker boats. They hold the strake while it's being attached and fitted, preventing it from slipping.

Given their specific purpose, these clamps are hard to find, unless you’re visiting very specific hardware stores or ordering online..

Toggle Clamp

Confusing at first look due to the pivot and lever system in combination with all the various toggle clamp designs, they're actually quite simple to use once installed. There are horizontal, vertical, push-pull, and pull-action latching designs.

There's only one "side" or jaw that is pushed up against the board, for example, which sandwiches it between the toggle clamp and the surface it's resting on.

Step Clamp

Step clamps are designed to be used with step blocks, both of which have serrations on them that let you tighten the clamps in incremental steps. If you look closely you'll see how the blocks appear to have a tiny stair case on them.

These steps then seat perfectly within each other to create a lot of surface area friction and vertical and horizontal resistance to keep the clamps from slipping. They're incredibly strong, though take a little longer to use.

Picture Frame or Corner Clamp

These are hard to describe, but they're like two clamps in one that hold two pieces of wood, plastic, or metal together at ninety degree angles. Like their names suggest, they're designed to hold picture frame right angles together while the wood glue dries This application goes for all types of woodwork and types of glue, simply holding things tight until the glue cures.

These can be used in welding and any other type of woodworking projects as well. If you have four corner clamps you can build entire squares or rectangles all at once instead of waiting four times as long to deal with each of the corners.

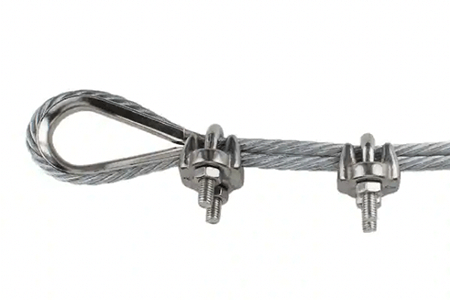

Wire Rope Clamp or Cable Clamp

These go by many names, such as wire rope clamp, cable clamp, U-clip, U-clamp, etc. They all describe the purpose or shape. The saddle of this clamp has a curved indention so one section of a rope or cable can rest in it. Then the U-shaped bolt accepts and squeezes the portion of the rope or cable that has been folded back on itself.

The purpose is to create a loop at the end of a rope or cable so it can be attached to a hook or carabiner. The bolt clamps down onto the saddle base by tightening two nuts. The tightness as well as the friction keeps the cable from slipping. This means if a cable or rope has any vinyl coating, for example, you need to strip that coating away where the clamps are, or you'll reduce its effectiveness greatly.

Types of Clamps for Every Project!

While this may seem like a lot, we’ve barely even scratched the surface of the ‘how many types of clamps exist’ iceberg. There are several more clamps, such as pinch dogs and so on and so forth.

This means that whatever your need, there truly is one particular kind of clamp to satisfy the same. However, don’t worry too much if most of this information went over your head—most clamps are extremely versatile.

Very few are single-purpose and therefore, can be used interchangeably. Unless you’re very specifically building a clinker boat, a C-clamp will serve you just as well as a power clamp, but for the best results, it’s worth knowing what types of clamp should be used and when.