17 Types of Fiberglass & Their Various Properties & Applications

Author: Rick Worst | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

The various types of fiberglass are probably one of the biggest game-changing innovations in the construction and interior decor industry. While the material has been around since the end of the 18th century, fiberglass usage was limited to the aviation industry and other industrial applications.

Today, though, fiberglass has found its way into many sectors (even taking over some!) from the military and defense to shower enclosures and bathtubs.

The popularity is understandable—fiberglass is less expensive, stronger and more flexible than both normal glass and carbon fiber. It’s also super lightweight and malleable, taking forms easily on molding.

17 Types of Fiberglass

However, not all fiberglass is made equal—there are many different types of fiberglass with different features and properties.

Whether you’re building a new house, renovating an old one, or just like learning new things, here’s a breakdown of the different types of fiberglass and their features.

A-Glass Fiber

The most commonly available type of fiberglass, A-glass fiber also goes by the names ‘alkali resistant glass’ and ‘soda-lime glass’. So common is this glass that 90% of all manufactured fiberglass is alkali glass.

A-glass fiber finds maximum usage in the food and beverage industry, used for making jars and containers for food and types of drinking glasses (‘container glass’). A-glass fiberglass types are also used for making window panes (‘flat glass’), while tempered A-glass fiber is also used to make bakeware.

A-glass fiber is quite popular for its chemical stability and its relatively inexpensive nature and toughness. It’s also easy to work with and can be melted and softened multiple times, making it relatively more recyclable (and eco-friendly!) than glass.

C-Glass Fiberglass

Chemical glass or C-glass has an incredibly high resistance to chemical impact (which probably explains the name!). Since C-glass holds its own in a range of environments, it’s the “go-to” material for chemical storage.

Even in extremely corrosive environments, C-glass types of fiberglass display and provide structural equilibrium, owing to the presence of high amounts of calcium borosilicate, as well as other high-pH chemicals used in its manufacture.

C-glass is generally used as surface tissue for pipes and tanks that are used for storing chemicals, water and other liquids, in the outermost laminate layer.

D-Glass Fiber

D-glass fiber has boron trioxide in it, which leads to a low dielectric constant—a fact that it is known for and a property that makes it the ideal fiberglass type for optical cables.

D-glass fiber also has an extremely low coefficient of thermal expansion (meaning that it doesn’t expand with increasing temperatures), owing to the presence of borosilicate in it.

Due to this feature, D-glass fiber is an extremely common material in cookware, bakeware, and utensils, as well as electrical appliances.

E-Glass Fiber

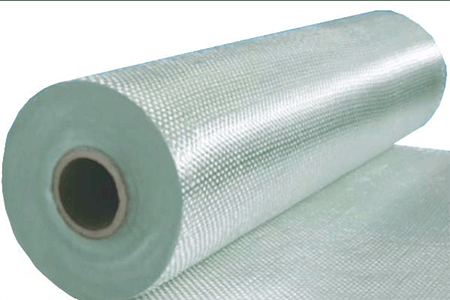

Commonly known as ‘electrical glass’, E-glass types of fiberglass are a composite lightweight material that find widespread usage across industries, from marine to aerospace to other industrial applications.

E-glass is also the main component in bonded fiber fabric (due to which the material is also called E-fiberglass cloth)—an industry-standard cloth that boasts both cost efficiency and excellent performance, with a draping feature that lets you work cleaner.

Fiberglass cloth is generally used in industrial and non-apparel areas. E-glass can withstand high degrees of mechanical impact, due to which it’s popular and used extensively in nearly every industry.

ECR Glass Fiberglass

Also called electronic glass fiber, ECR glass fiber boasts extreme resistance to corrosion and alkalis, high mechanical strength, and excellent waterproofing and is a level up on normal E-glass fiber.

One of this material’s biggest draws is that the manufacturing process is more environmentally friendly than other fiberglass types—quite frankly, the need of the hour and a need that thankfully, many companies are coming to recognize and address!

ECR glass fiber is generally used in making transparent GRP panels, made of calcium aluminosilicates that give it strength, electrical conductivity, resistance to acid corrosion, higher surface resistance, lower electrical leakage, higher heat resistance and better mechanical properties (phew!).

ECR glass is also more durable, giving you high performance at low costs.

S-Glass, T-Glass, or R-Glass Fiber

Despite the three different names, we’re talking about the same fiberglass. S-glass, T-glass, and R-glass are trade names for a type of fiberglass with extremely high tensile strength and modulus, especially when compared to E-glass.

The acidic strength and wetting properties in these types of fiberglass are also higher, obtained by reducing the filament diameter.

S-glass is generally used in the aerospace and defense industries, especially in rigid ballistic armor in the latter.

Due to this specific usage, this fiberglass is produced in lower volumes, which, in turn, means that the cost is higher than other types of fiberglass. Its excellent performance also contributes to its high price.

Z-Glass Fiber

Used largely in industries such as concrete reinforcement and 3D printing, Z-glass fiber is used when a product needs to have an increasing amount of transparency, such as 3D printing carbon fiber.

These are very resistant types of fiberglass that can withstand high and low temperatures, acidity and alkaline environments, salt in the air, and is even scratch resistant. It's very durable and consistent. This reliability make it well sought after.

Advantex Glass Fiber

One of the latest innovations in the fiberglass industry, Advantex fiberglass blends ECR fiberglass’ high resistance to acid corrosion with the excellent electrical and mechanical properties and low price of E-glass!

Advantex fiberglass is commonly used in industries where thermal fluctuation is commonplace, like in various types of furnaces, as this glass has a very high melting point.

Advantex fiberglass has high quantities of calcium oxide, just like ECR fiberglass and hence, is also commonly used in industries where resistance to acid corrosion is a necessity.

Therefore, Advantex fiberglass is used in power plants, mining, gas and oil industries and in marine applications such as in wastewater and sewage systems. you can find it being produced by popular companies such as Owens Corning.

AE-Glass Fiberglass

AE-glass types of fiberglass have the core feature of being an alkali resistant fiber while also having a low electrical conductivity.

AR-Glass Fiber

Alkali-resistant glass is specifically designed to be used in concrete, with a composition that involves the specific formulation of zirconia at optimum levels.

This Zirconia is what makes the fiberglass suited to concrete and provides the latter with the strength and flexibility to keep it from cracking.

Additionally, since AR-glass is not affected by pH changes, it doesn’t dissolve in water and can be easily added to steel and concrete mixtures.

AR-glass is also used in mortar and concrete reinforcement applications, due to the high tensile and modulus strength. The fact that it doesn’t rust is also a huge bonus.

S2-Glass Fiber

The man o’ war in the fiberglass race, S2-glass fiber is the highest performing racehorse in the market. It has a relatively higher level of silica in its make, resulting in enhanced weight performance, temperature resistance, impact resistance and compressive strength.

S2-glass has around 85% more tensile strength than normal fiberglass, which also gives it better durability, fiber toughness, modulus of resistance and, therefore, better impact capabilities and about 25% more linear elastic stiffness that lets it tolerate damage better.

Given all of this, you’d think that S2-glass would cost a lot, but it’s also surprisingly cost efficient!

M-Glass Fiberglass

Owing to the beryllium in its composition that adds extra elasticity to the fiberglass, M-glass types of fiberglass are used in a range of glassware applications, from packaging to housing to building to tableware.

Chopped Strand Mats

Chopped strand mats are composed of 3-to-4-inch fiberglass fibers. The strands in these mats are randomly arranged and don’t have a fixed orientation, unlike woven fabrics.

Due to the relatively short length of the fibers, this type of fiberglass is not very strong, but it’s the least expensive and therefore, most commonly used, despite the weakness.

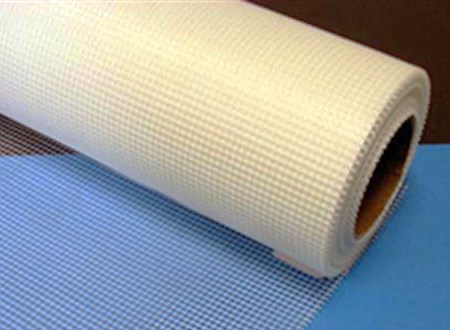

Woven Fabrics Fiberglass

Woven fabrics are pretty strong, with the fibers neatly oriented in two directions and bundled into yarns. This makes the material strong and hardy.

Continuous Strand Veil Fiberglass Mats

Veil mats have continuous fiber strands that are arranged in thin, randomly-looped piles, with a consistency like that of tissue paper.

Due to this relatively delicate nature, veil mats are not used for building or structural applications; instead, they’re used for purposes such as minimizing print through and cut through in the molds of heavier reinforcing cloths.

Veil mats are also used with sandwich cores—they’re placed directly over the core to maintain the perfect bond-line thickness. In case some types of vacuums aren't used, veil mats keep the excess resin from falling in the honeycomb-core cells.

Tow & Roving Fiberglass

As tow and roving, fiberglass has the highest number of achievable properties. Such fiberglass comes in spools that can be unrolled and cut as needed or fed into filament winders.

The material’s fibers need to remain taut and tensed to retain their mechanical properties, though. This makes shipment and installation a bit tricky.

3D Stereo Fiberglass

3D stereo fiberglass is often constructed like continuous strand mats but there are two deck layers (the stereo part) where the strands are also weaved between these mats (the 3D part). This increases the visual thickness though it can be collapsed with force.

The intermediate connecting fibers can be made of varying densities or thicknesses. And most interestingly, the shape of their weave can be chosen, such an O-shape, V-shape, and even an 8-shape.

Common Types of Fiberglass Characteristics

You'll have noticed a lot of letters above in the names of these various fiberglass types. These refer to the following characteristics:

- A for alkali resistance

- C for chemical resistance

- D for a low dielectric contant

- E for low electrical conductivity

- M for high tensile modulus

- S for high tensile strength

- ECR for long term acid resistance but short term alkali resistance

- R & Te for high tensile strength at high temperatures

Don't confuse ECR fiberglass with E-glass. All of these various properties provide mechanical strength, incombustibility, dimensional stability, thermal conductivity without electrical conductivity, and dielectric permeability. Notice that none mention fire safety since fiberglass isn't flammable until extremely high temperatures.

These properties explain why we find fiberglass being used in cooling towers, docks and marinas, food processing, as plywood alternatives, power generation, pulp and paper industries, automotive and aerospace industries, in types of tile, aquatic industries, and chemical industries.

Types of Fiberglass for Every Use & Industry

Fiberglass comes in a range of shapes, sizes, and forms, with a range of properties. This is, by no means, an exhaustive list—you’ll find further differentiation based on form, usages, applications, and properties.

However, ultimately, knowing the base material and property will help you tell your fiberglass types apart, which is what this guide covers.

So whether you’re renovating your house or buying a new bathtub or just randomly chanced upon this article, you are now equipped enough to show off your newfound knowledge on the many different types of fiberglass.