16 Types of Furnaces That Generate the Heat You Need

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

For ages (since the times of Romans, actually!), different types of furnaces have been heating homes across the world, stationed at the core of their central air systems in attics, crawlspaces, basements, and closets.

These already-popular heating options, loved for their high efficiency, extremely long lives and almost zero operating noise, only became more popular with the introduction of energy-efficient, eco-friendly innovations.

Types of Residential Furnaces

Furnaces (also referred to as ‘forced-air systems’) are supremely flexible because there are so many types—whatever your needs are, you can almost always find a furnace to suit them. Read on to find out more about the many types of furnaces that exist.

Gas-Fired Furnaces

Traditional gas-fired furnaces are probably the oldest types of furnaces and perhaps, for this reason, are also the most commonly used, like the gas types of air conditioners you find in homes.

They account for 57% of all furnaces used in American homes, despite being more expensive than oil furnaces (you’ll have to also pay for the installation of a municipal gas line).

Gas furnaces, despite being panned for not being eco-friendly, are actually the cleanest burning fuels among all non-renewable energy sources. Additionally, a modern gas furnace needs to have an AFUE rating between 89 and 98%.

Gas-fired furnaces can last up to 25 years with the right care—providing the right care is also easy since they’re low maintenance. Watch out for carbon monoxide leaks, though—you may have to install carbon monoxide detectors if you’ve got one of these furnaces around.

Wood-Burning Furnaces

Another traditional type of furnace, wood-burning furnaces are ideal for homes situated in regions where firewood is aplenty. The wood, burned in the firebox, emits heat that circulates through the ductwork, just as it is with gas furnaces.

Wood-fired furnaces can be a bit of work, though, since they have to be manually fed and tended to periodically, even if you're using wood pellets. You can think of these furnaces as extremely powerful space heater alternatives.

Therefore, they can be slightly impractical and inconvenient, especially if no one is going to be around while the furnace is in use. For this reason, a majority of folks use these as backup heat sources.

Traditional wood furnaces have AFUE ratings between 40 and 55%, though newer models may max out between 75 and 90%.

Oil-Fired Furnaces

As you’ve probably guessed, oil-fired furnaces are fired by oil. Oil-fired furnaces are also very ‘high maintenance’!

Though these furnaces come with a lifespan of 30 years and are less expensive than gas furnaces, the amount you’ll be shelling out for the oil (mostly imported) will negate anything that you saved on the price you paid for the furnace itself. Oil prices are also notoriously volatile.

Oil-fired furnaces need on-site storage tanks for the oil. They’re also not the most environmentally sustainable solutions, though modern oil-fired furnaces need to have AFUE ratings between 80 and 90%.

Propane Furnaces

You've heard of propane, undoubtedly. It's a byproduct of gas production and when working with oil. It can be stored in tanks, that you've probably seen in cooking grills on various types of patios.

If you can't access gas or oil from your utility company, then propane is a great option. Almost 10% of houses in the United States take advantage of this option.

Electric Furnaces

We won’t lie—an electric furnace will cost more than either a gas or oil-fired one while operating and you’ll be racking up quite an electricity bill. But like the various types of water heaters, they're becoming more efficient and cheaper to run.

Despite that, electric furnaces are more beneficial to both consumers and the environment for a range of reasons. With AFUE ratings between 95-100%, you can also recoup your expenses through higher efficiency.

In the case of the former, electric furnaces use one of the most widely available, renewable sources of energy as fuel. Electricity is available all over the United States and in some areas, more easily available than either oil or gas.

In the case of the latter, electric furnaces are non-polluting or at the very least, significantly less polluting than oil and gas furnaces.

You can also run electric furnaces on solar energy (this will even result in major savings thanks to the cheapness of the energy source as well as government incentives). The technology has advanced from natural draft, forced air, forced draft, and on to condensing furnaces.

Waste Oil Furnaces

Waste oil furnace types use waste oil that can no longer be used to accomplish its original purpose, such as used vegetable oil or automotive oil.

Therefore, waste oil furnaces are deemed extremely eco-friendly contraptions, recycling oil meant for the dump.

The truth, though, is that waste oil often contains tons of pollutants, such as detergents, lubricants, lead, chromium, and PCBs.

Burning this oil releases these pollutants into the air, for which reason, the EPA regulates which oil can be burnt, even requiring permits, properly constructed types of chimneys, and chimney emission certificates in certain cases.

Dual Fuel Furnaces

Dual fuel furnaces are extremely convenient furnaces that act as gas furnaces during the cold months and as a heat pump when it’s not so cold.

You’re already familiar with how the former works; the latter removes heat from the outdoors and brings it into your home, passing through an air handler that warms the air while it passes over hot-refrigerant coils.

Dual fuel furnaces are considered super efficient in terms of their energy use and cost effectiveness, once you get past the initial upgradation and installation costs.

Modulating Furnaces

Though modulating furnaces are on the more expensive side, many people deem them worth the investment. Modulating furnaces adjust the amount of gas burnt so that it can reach the target temperature on the thermostat.

Therefore, modulating furnaces can pinpoint the temperature more accurately—in fact, with only a 0.5 degree Fahrenheit margin of error, compared to 4-6 degrees on other furnaces.

These home furnace types also have lower energy requirements but still give you the heat you want. This is opposed to single stage and two-stage furnaces than are less efficient.

Types of Industrial Furnaces

Industrial types of furnaces commonly use combustion gases and fuel and work at much higher temperatures than ones for residences.

These include blast furnaces that come in direct contact with the gases and fuel, reverberatory furnaces that indirectly come in contact with fuel but directly with the gases, and muffle furnaces that are indirectly connected to both the fuel and gases.

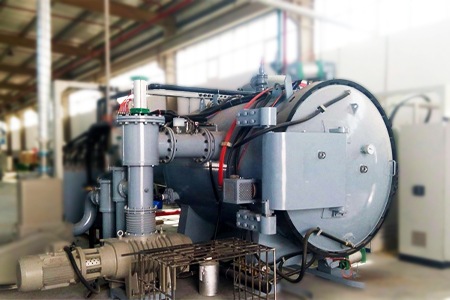

Bell Furnaces

Bell furnaces may be gas-fired, heated electrically, or have thermal re-circulation heating systems with movable domes that can be frequently lifted throughout the controlled atmosphere or vacuum processes.

Bell furnaces can be used to treat strips, coils, rods, and sheets, among others. They can normalize, anneal and temper, whether single or multi-stack.

Box Furnaces

With box furnaces, consistent airflow management is ensured thanks to the swing-open doors or vertical lifts insulating the furnace. These furnaces are used to temper, cure, heat treat, calcine and preheat, among other processes.

Box furnaces are available as both gas fired and electric and accept heavy loads. These are commonly used in laboratories and industrial settings.

Pit Furnaces

Pit furnaces, also known as top-load furnaces, produce different temperatures within a secured working chamber that has a controlled atmosphere inside.

These are available as both gas fired and electric and come in many sizes. Pit furnaces are most commonly used in machine building, mining, and manufacturing automotive and aircraft parts.

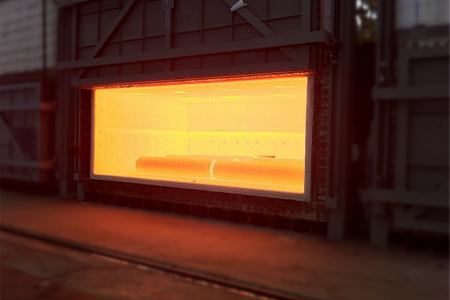

Forging Furnaces

Very similar in appearance to pizza ovens, forging furnace types are open-hearth furnaces that are most commonly used for preheating.

These transmit heat via radiation so that metals can reach the temperature they should for forging or for hardening to stop.

Blooms, steel ingots, and parts are generally heated and reheated in heavy-duty forging furnaces. Forging furnaces also come in the forging box version.

Quenching Furnaces

Quenching furnaces have rapid, controlled cooling to harden materials. These furnaces feature enclosed heating chambers to prevent phase transformations.

Quenching furnaces mainly aim to prevent overheating and uneven heating, but you can also temper after the quenching to increase the toughness.

Generally, bearing components, gears, construction, fasteners, and components of agricultural machinery are processed in these furnaces. Quenching furnaces can be gas fired or electric.

Rotary Furnaces

Rotary furnaces are generally mounted on barrel-rotating drives throughout the heating treatment, with a barrel lining welded from steel.

Rotary furnaces provide uniform heat and good material contact and the internal heat source can be either electric or gas fired. These furnaces are generally used for oxidation and calcination.

Salt Bath Furnaces

Salt bath furnaces use extremely intense and fast heating to achieve quick results in metals. These are typically electric, though sometimes, they can be heated externally with a gas-fired or electric unit. Salt bath furnaces can go up to 2,350 degrees Fahrenheit if required.

Salt baths are used for a range of purposes, such as surface treatments through carburization or salt nitriding ordinary surface cleaning or neutral temperature change without affecting surfaces. They can also be used for treating stainless steel and nickel-chrome alloys and other edge tools.

Tempering Furnaces

Tempering furnaces are typically used to increase toughness in ferrous metal products. The intense heat strengthens materials, impacting the alloy formation and energy absorption.

To achieve a balance between elasticity and strength, tempering furnaces are used with quenching furnaces. To achieve the desired material characteristics, these furnaces, when used together, must maintain uniform temperature levels.

Of course, this is, by no means, an exhaustive list of industrial furnaces — there are still many others such as vacuum, laboratory, shell baking, roller hearth or raised, pusher, conveyor, aluminizing, brazing, metal melting, and calcination, to name a few—but we hope that you now know a little bit about the types of furnaces that do exist.

Types of Furnaces for Every Residence & Industry

Furnaces are used for a range of reasons and in a range of settings, from residential to industrial. The options are many, whether we're talking about home furnace types or for industry. The best part is all of the different types of furnaces for home and otherwise are becoming more effective and efficient.