The Different Types of PEX Pipe for Each Application

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

Are you replacing piping around your home? The various types of PEX pipe, otherwise known as "cross-linked polyethylene," are the industry-standard material used in plumbing applications across America and throughout the world now.

Whether you're a contractor looking for plumbing for new construction or a homeowner doing a DIY plumbing project, PEX is the superior choice over materials like copper and galvanized steel. Unlike galvanized steel and copper piping, PEX is easy to install and much less expensive.

This post unpacks everything you need to know about this durable and affordable plumbing material. We'll examine the different types of PEX and why you should consider it for your project.

The Different Types of PEX Pipe

There are several different grades of PEX piping available for plumbing applications. If this is your first time working with PEX, the grades might be confusing. However, it's easy than you think, and we'll unpack the differences in this post.

Plenty of manufacturers specialize in PEX piping, and it's readily available for plumbing stores across America. There are around 20 PEX pipes, each with a unique, and often niche, application. For instance, there's a different type for cold or hot water applications and indoor or outdoor use.

So, it's essential that professionals and DIY enthusiasts understand the difference between the grades and which one to use in each application, how to insulate PEX pipe, etc.

While there are over 20 different grades of PEX piping, many you'll never need or encounter, we'll focus on the four most common types for use in residential plumbing applications.

PEX A

This grade is the most robust and durable option for home plumbing use. PEX A has plenty of flexibility and excellent recovery from kinks, making it a leak-proof piping option for your home. If traditional materials like PVC or copper experience a kink, your only option is to replace the pipe.

However, PEX A pipes only require the plumber to heat the pipe, and it returns to its original shape, eliminating the need for a replacement. It's a great choice for use in areas with limited space. The price point for PEX A is favorable, being lower cost than copper or galvanized and more affordable than other PEX grades.

Here are a few common applications for PEX A pipes:

- Crimp or clamp fittings

- Expansion fittings

- Press-style fittings

- Push & connect fittings

If your plumbing project involves corners and turns, PEX A offers you the best option for working with close-radial bends in the pipework. It's much easier to hide the pipes without needing to do a bunch of 90 degree turns, which are a pain and create more chances for leaks.

PEX B

Your plumbing project may require you to work with pipes optimized for straight and long tube replacements. If that's the case, PEX B is the ideal choice for this application. If you're looking to save on your plumbing project budget, PEX B helps you overcome the challenges PEX A can't solve.

Straight, long applications require a less-flexible tube that's stiffer and rigid, stopping sagging over distance. The rigidity offered by PEX B tubes makes them ideal for these applications, giving you the perfect option for covering long distances.

Here are some uses of PEX B piping:

- Push & connect fittings

- Press-styled fittings

- Cold expansion fittings

The only issue with PEX B types of PEX pipe is its stiffness results in a higher risk of cracking instead of bending like PEX A. As a result, installing PEX B pipes is a little trickier than PEX A.

That's the main consideration in the PEX A vs. PEX B comparison. There is one more thing to remember, though. PEX B comes with excellent chlorine resistance, and it's the ideal choice for high-pressure applications because there's minimal risk of it bursting. That's the difference between PEX A and PEX B in a nutshell.

PEX C

For DIY or general plumbing applications, PEX B & C might seem to have similar properties. However, each of these grades has very different properties. One of the differences between the two is the hardness. PEX C is slightly softer than PEX B.

The slight difference in softness in PEX C means it's more susceptible to kinks and bends. However, the manufacturing costs of PEX B are lower, making it the more affordable option for DIY installations where homeowners are looking to drive down project costs.

PEX Pipe Types Based on Barriers

As mentioned, some PEX pipes, like PEX AL PEX, come with internal barriers, making them suitable for specific plumbing applications. There are three categories of PEX barrier piping:

- Oxygen Barriers

- No Oxygen Barriers

- Aluminum Barriers

Let's unpack the differences between each and how they impact the application of each type.

PEX With Oxygen Barriers

This type of PEX tubing consists of pipes with an intact oxygen barrier. Oxygenation of the piping is one of the factors causing corrosion in standard copper and galvanized pipes.

As a result, these types of traditional tubes allow byproducts from the corrosion process to enter the water heating system, resulting in clogging of the components in these appliances.

Such applications as underfloor heating or baseboards benefit from the use of PEX tubing with an oxygen barrier. These PEX pipes offer excellent corrosion resistance, and you get it in PEX A & B grades. The most common sizes of PEX A & B pipe with oxygen barriers is ½ inch, but you also have ⅜, ⅝, and ¾ inch sizes readily available.

PEX Without Oxygen Barriers

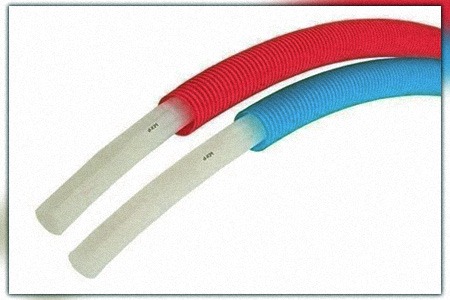

Most plumbing applications require pipes with non-oxygen barriers. PEX A and PEX B are also available in non-oxygen barrier grades, with plenty of color options, including red, white, and blue. There's also plenty of size variety, with options ranging from ¼ inch to 3 inches.

If you're looking for piping for indoor plumbing applications, then your best bet is to go with ½-inch PEX pipes for optimal flow rate.

PEX With Aluminum Barriers (PEX AL PEX)

These types of PEX pipe grade is one of the most expensive options because it features an aluminum barrier inside the tubing. As a result, the piping is very rigid and exceptionally strong, allowing for fitment across distances without any sagging in the pipe.

PEX AL PEX also provides an effective oxygen barrier making it the ideal choice for use in heating applications, such as water moving from the heat pump or geyser.

Why Choose PEX Pipe for Plumbing Applications?

One of the main reasons for the increase in the use of PEX in plumbing applications is its ability to provide custom applications. It's a highly flexible material, meaning it won't split, crack, or dent like galvanized steel or copper piping.

You don't need complicated installation practices like brazing copper or gluing and soldering. PEX tubes are easy to cut to length, and a range of fittings allows for easy installation around corners.

Copper rings and brass fittings are typically used to secure PEX pipes in plumbing applications. If you understand plumbing requirements in homes, then you'll appreciate the simplicity of installation PEX offers any installation.

With PEX, you get a carefree installation that eliminates the need for gluing involved with PVC pipes, making a job much less messy and cumbersome. There's no curing time; you can use the plumbing right after fitment.

Why Do Plumbers Use PEX Pipe?

Plumbers love PEX piping. Traditional materials like copper piping are used to dominate the plumbing market, with many professionals turning to PVC solutions in recent years due to their lower cost. However, with copper prices going through the roof and the solvents in PVC bonding agents being pretty toxic, PEX is a user-friendly, cost-effective solution replacing these materials.

If we compare these traditional alternatives with PEX, we find there's less need for fittings and connections, allowing plumbers to finish jobs fast. Since PEX is a form of plastic similar to PVC, you don't have to worry about it rusting like your do with copper or galvanized pipes.

What Types of PEX Pipe Should I Use in My Plumbing?

Now that you have an idea of the common types of PEX piping, it's time to settle on the right grade for your application. There are several factors to consider when choosing the right type for your plumbing job:

- The length of pipe required

- The curves and bends the plumbing will have to take

- Hot or cold water applications

- Internal or external use

- The flow rate required through each pipe

- Whether you'll bury the PEX pipe

Your selection of the right PEX pipe for the job will also depend on the right size tubing for the application. For example, a ½ inch PEX pipe is the ideal size for branching plumbing lines from the main water line entering your property.

If the main water line is a ¾ inch pipe, then a ½ inch pipe is ideal for branching off from the water main. You'll find you get good flow rates and water pressure from this size. These connections are ideal for installing lines to the shower, bathroom, kitchen sink, and laundry without impacting the flow rate or water pressure in these areas.

Due to its all-purpose attributes and properties, PEX A offers the best grade for these plumbing applications. However, you can't assume it's the best grade for all applications in your residence.

Different Types of PEX Pipe for Each Purpose

If you're having trouble deciding on the right types of PEX pipe for your home plumbing job, call the experts for help. Plumbing stores will give you advice on choosing the right PEX grade for your project.