How to Strip a Wire of its Insulation Sheathing Easily

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

Are you fixing something electrical in your home? Chances are you'll have to strip some wires for the job. If you've never stripped wires before – don't stress; we have you covered. We put together this guide on how to strip a wire, giving you everything you need to know about stripping any wire at home.

What Kind of Wires & Cables Need Stripping?

Stripping wires is an important skill to master. If you plan on doing any electrical project at home, you'll need to know the ins and outs of this task sooner or later. Stripping an electrical wire removes the outer insulating sheath without slicing through the wires inside.

The wires feature construction with highly conductive materials, like copper to ensure optimal unresisted electrical flow. Moist worse inside the sheath also has an independent sheath around them to prevent the currents from mixing and causing a short.

Let's look at the different types of wires you'll find in DIY stripping tasks.

Plastic Sheathed Cables

You'll strip plastic sheathed cables in two stages. First, the outer sheath requires you to slide the cable into the notch on your stripping tool, matching the correct gauge.

Stripping plastic sheathed cable is performed in two primary stages. You'll squeeze the wire to cut through the sheath and slide it off to expose the inner wiring. I had to do this recently when my garage door was only opening a few inches and I had to move and realign the sensors.

You can score the cable with a knife if you don't have a stripping tool, but we recommend you use a stripping tool to avoid damaging any of the thin wires.

Electrical Cords

Stripping electrical cords, like those running from the kettle or toaster, is pretty simple. We recommend using the stripping tool, but a sharp knife is usually okay for the task.

If you're using a knife, score into the cable and move the blade slowly around the jacket without damaging the internal wires. Once you've removed the jacket, strip it back a half inch and remove the sheath from the two or three inner wires.

Underground Cables

You can score and strip underground cables with a knife because they have a sheath around each conductor. You'll need a stripping tool for the task.

Instead of scoring in a circular fashion, you'll cut lengthways to remove strips as you go around the circumference. If you nick or gouge the cable, you'll have to cut the cable at that point and start again.

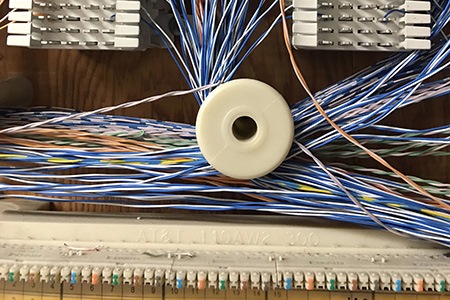

Communication Wires

You'll need a specialized wire stripping tool to strip cables like high-speed internet lines. These cables contain many small sheathed wires inside, requiring care to strip them successfully. If you know how to strip a wire (a basic wire), these will still give you a challenge. Cutting a wire is one thing, but these are made of lots of wires, each with their own insulation.

Coaxial Cables

You'll use a test cutter to strip these cables. This tool has blades you adjust using screws to control the cutting depth. You can peel the outer sheath away with a knife, but we recommend using a stripping tool for the best results.

Thin Wire

These wires are challenging to strip with a knife, and you'll probably end up cutting through the conductor wire. We recommend using a stripping tool adjusted to the correct depth, like the one seen just below. Imagine if your doorbell is buzzing and you need to install new wires. This is the kind of wires and tools you'd be dealing with.

How to Cut & Strip Electrical Wires With a Wire Cutter

There are several tools available for stripping wires. The lineman's pliers, wire cutters, and diagonals are all examples of tools equipped for the task. Diagonals are available in several sizes to suit different gauge cables and wires and are the best choice for cutting thin wires.

The cutting block on needle-nose pliers is also useful for snipping small wires, scoring and removing sheaths, and reaching wires in tight spaces. Lineman's pliers are ideal for cutting through heavy-gauge wiring and non-metallic cables. They're both essential tools for how to cut wire, but what about stripping?

Wire strippers come in several styles, making it easy to strip wiring in solid-core, small wires with gauges ranging from #10 to #18. Graduated wire strippers featured on the jaws of multipurpose tools are also useful for smaller projects.

Here's a three-step guide to using a wire stripper. This is how to strip a wire in the large majority of cases.

Step #1 – Place the wire in the correct slot for the gauge wire you're cutting. Otherwise, adjust the screw on the side of the tool to the correct size and depth.

Step #2 – With the wire positioned at a slight angle, press the handles of the tool together. Rock the stripper back and forth to cut the insulation without damaging the wiring.

Step #3 – When you've cut through the insulation, pull the stripper to the front of the wire to remove the sheath.

How to Strip Wires Without Using a Wire Cutter

You can always use a utility knife for stripping electrical wires if you don't have a wire stripping tool. It's not optimal, but it is possible. I've done it countless times when I've been too lazy to dig in my various tool chests to find the wire stripper.

Step #1 – Lay the wire flat on a horizontal surface.

Step #2 – Cut through the insulation carefully, going all the way around the sheath. Don't cut through the wire.

Step #3 – Strip away the insulation.

This method is easier when stripping solid copper wires. You don't have the chance to do as much damage and make mistakes as you do with braided copper wire strands.

How to Cut & Strip Romex Cables

You can use heavy-duty diagonal pliers or lineman's pliers to cut Romex or similar non-metallic electrical cables. The larger the cable, the more pressure you'll have to apply to get through the sheath, as they can be quite tough to remove.

Before stripping the insulation from the wire conductors, you'll remove the cable's outer plastic sheath. Opening non-metallic cables and exposing the individual conductor wiring is a process called "ripping."

To rip flat cables, use a utility knife or cable ripper. This is how to cut electrical wire using three different tools.

Using a Cable Ripper

When cutting electrical wires with a cable ripper, slide the ripper over the sheath first. Squeeze the handles, and the ripper cuts into the outer sheath to the correct depth, then just drag it off the end of the wire. This is the same procedure you use for a wire cutter or wire stripper as seen above. It's how to strip electrical wire in almost every standard case.

Using a Utility Knife

If you're using a utility knife for the job, pay attention to the contour of the wires to avoid nicking or cutting the internal wires. Work on a horizontal, flat, or vertical surface and cut the sheath away from your body. Don't cut towards yourself as you risk a severe injury. That's always rule number one when cutting anything.

Using a Diagonal Ripping Tool

Slide the ripping tool onto the flat cable and press the handles to score the sheath. Bend the flat cable until the scoring cracks, exposing the wires underneath. Peel away the outer sheath to expose the wires. Snip the peeled sheath to remove it from the other materials. Leave only the wires.

How to Join Electrical Wires

So now you know how to strip a wire. If you have a basic understanding of how to connect wires and the right tools, it's an easy task to join them. Ensuring you connect the wires properly is essential if you want a safe and effective job.

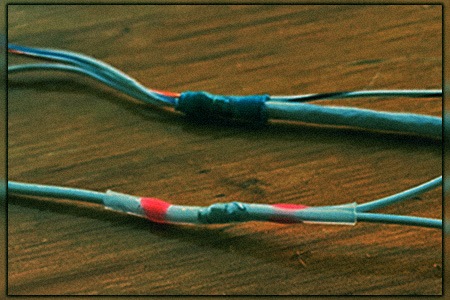

Poorly splices or joined wires can create shorts, leading to electrical fires. Compression sleeves and wire nuts are the ideal components for connecting wires. Your local building codes and project requirements determine which one you'll need for the task.

Two kinds of connectors splice wires together safely and strongly—wire nuts and compression sleeves. Which connector you use will depend on your project and your local building codes. Wire nuts are connectors with a thimble shape featuring construction with hard plastic.

The nuts twist over the ends of the stripped and joined wires, strengthening the connection while concealing the bare wires. Since wires come in different gauges, you'll need to use the right wire nut for the task to ensure safety and a secure connection.

Manufacturers color-code wire nuts to distinguish the sizes. The smallest nuts are grey, suiting sizes to #22 American Wire Gauge (AWG), and the red nuts are suitable for #10 AWG. Using the wire gauge helps you select the right wire nut for your project.

Follow this five-step guide to connecting the wires using the wire nuts:

Step #1 – Strip away approximately an inch of the insulation from the ends you want to splice together using your wire stripping tool of choice or utility knife.

Step #2 – Twist the ends of the wire together in a clockwise direction. Pinch the ends and then twist if you're connecting large wires with lineman's pliers.

Step #3 – Trim ¼ - ½ an inch from the ends of your twisted wires.

Step #4 – Screw on the wire nut in a clockwise direction until you have a secure fit. The lines should stay pout if you give them a light tug, and you must ensure there's no exposed wire showing outside the nut.

Step #5 – Wrap the wire nuts with electrical tape using a clockwise wrap.

Joining Electrical Wires Using Compression Sleeves

Using compression nuts to connect wires provides a more secure and permanent connection than using wire nuts. Many building codes require the use of compression nuts instead of wire nuts. These nuts look like bullet shells with the ends removed, and some come insulated.

Fitting the compression sleeves is a little more challenging than using wire nuts, but with the right method, you'll find it's an easy task. Follow this step-by-step process for success with the job.

Step #1 – Use your wire stripping tool to strip the insulation sheath from the wires. Expose an inch of the underlying wire and twist them together.

Step #2 – Cut around 1/2 inch off the wire's end.

Step #3 – Slide the compression sleeve over the ends of the stripped wires and crimp the sleeve using a pair of pliers or a multipurpose tool.

Step #4 – Wrap the compression sleeve with electrical tape to finish the job.

And That's How to Strip a Wire

While you can get the job done using a utility blade or even a pocket knife, your best move is almost always going to be using a wire cutter, which will have many options to deal with wire of most any gauge.

There will be zero guess work or chance to mess up like you'd might have otherwise. And that's how to strip a wire. It's not hard and once you do it a few times you'll have full confidence in the process and can make it happen fast.