13 Types of Plywood: Grades & Prices for Your New Project

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

Few people tend to realize there are different types of plywood until you have a reason to need a lot of it for a specific reason. That's when we discover all of the grades, types, and prices.

For decades now, plywood has been a popular go-to option and homeowners have been commonly using plywood as an alternative to solid wood for everything, including the construction of the house.

Unlike any other kind of building material, plywood is not only versatile but extremely affordable too, all while offering the beauty of exposed wood and adding much structural stability.

Available in various types of finishes, plywood has a huge variety of uses like flooring, roofing, wall sheathing, cabinets, wardrobes, furniture, and also DIY projects.

13 Types of Plywood

In this guide, we will be discussing the various types of plywood so that you can choose the right one for your project and save time, as well as money. Understanding how plywood is made will help you understand why and how the different types will benefit you.

We'll also display typical prices you can expect per sheet of plywood at the most common size, which is 4 feet by 8 feet by 1/2 inch thick. These prices will vary by wood type, of course. We'll share the 13 plywood types and prices and then move on to the grades of plywood.

1) Softwood Plywood

Commonly made of spruce, pine, cedar, redwood, fir, or Douglas fir, softwood plywood is used for industrial and construction purposes for roof sheathing, sub-flooring, and exterior frames. Softwood plywood is also used for shelving, temporary flooring, in types of pallets, and in as flooring and siding in most small types of sheds.

Typically, softwood plywood is not suggested for outdoor use. Although it's a sturdy and strong material, it doesn't have the qualities that make it weather resistant for outdoor applications.

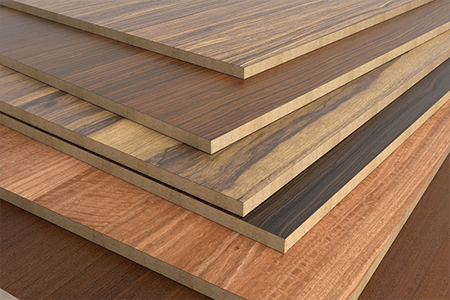

2) Hardwood Plywood

Made of the wood from dicot trees like maple, oak, birch, beech, mahogany, walnut, etc. Hardwood plywood has around 3 to 7 layers of wood that are glued together at right angles, offering an extremely strong finish.

Characterized by excellent stiffness strength and resistance to creep, hardwood plywood is used for applications like furniture, sporting equipment, packing cases, musical instruments, and other projects that need strong and sturdy frames.

The high impact resistance and planar sheath strength of hardwood plywood make it suitable for making heavy-duty wall and floor structures, doors, furniture, and cabinets.

Because of hardwood plywood’s smooth surface, it's known as interior plywood and it has excellent hardness and is wear and damage resistant.

3) Aircraft Plywood

This is the most durable kind of plywood types available and makes use of hardwoods like spruce, mahogany, and birch plus adhesives to create strong boards that are moisture and heat resistant.

The design of aircraft plywood incorporates very thin veneers that make it flexible and light while making it extremely strong for the heaviest applications. Most commonly, aircraft-grade plywood is manufactured from European birch veneers or from spruce.

African mahogany and birch veneers are then bonded together in a hot press over cores of hardwood like poplar or beechwood.

Another type of aviation plywood, basswood is more flexible and lighter as compared to birch and mahogany plywood but has lesser structural strength.

Typically, aircraft plywood is used in projects requiring industrial-strength woods such as boats, airplanes, and furniture that needs to hold heavy weights.

Aircraft plywood was originally used during World War II in the construction of air assault gliders and fighter aircrafts.

4) Tropical Plywood

Originally from Asia, tropical plywood is manufactured from mixed specials of tropical timber. Tropical plywood is now manufactured in South American and African countries too.

In terms of its quality, strength, density, and uniformity in layers, tropical plywood is much superior compared to softwood plywood.

Tropical plywood is used widely in countries like the U.S., the U.K., Japan, Taiwan, Dubai, Korea, etc. Premium quality tropical plywood is usually sold at a premium in several markets. Because of its low cost, tropical plywood is used for construction purposes in several countries.

5) Exterior Plywood

The most important concern with exterior plywood is how well it can handle the elements. With the right types of glue that are water and weather-resistant holding the veneer together, exterior plywood can withstand rain, wind, snow and other weather conditions for several years.

Exterior plywood consists of several veneers that are glued together, categorizing them as multi-ply, which offers additional strength. Exterior plywood offers a sturdy, strong, and robust frame that is durable and long lasting.

You can pick different types of woods for exterior plywood, depending on the climate of the area you live in. For instance, in areas that have harsh climatic conditions, hardwoods such as oak work very well, by resisting mold and mildew because of damp conditions.

6) Lumber Core Plywood

Usually comprising three plies i.e. two thin veneers on either side, sandwiching a thick core of a hard slab that is made from strips of wood, which are glued together, lumber core plywood is an excellent choice for constructing wide or long shelves in closets and cabinets.

The bending strength of the lumber core plywood and the ability of the inner core of the plywood to grasp screws easily, makes it an excellent choice for projects requiring strong screw hold.

However, one drawback is that, in the case of lumber core plywood, it's relatively poorly made. It may contain voids that reduce its strength and also the ability to hold screws.

7) Marine Plywood

Manufactured using core veneers and a durable face, marine plywood performs better in wet and humid conditions and can resist fungal attacks and delaminating better.

The construction of the marine plywood allows you to make use of it in places where it is exposed to moisture for long periods of time.

Each of the wood veneers is made from tropical hardwoods like Douglas fir or western larch, which are the highest quality woods, having a very tiny core gap, which reduces the chance of water being trapped in the plywood and hence, providing a stable and solid glue bond.

The marine plywood is varnished with an exterior water-resistant glue that helps to repel water, allowing it to withstand moderate water and moisture, but not entirely waterproof. You can finish the job by waterproofing plywood with polyurethane if you desire.

For plywood to be marine plywood, it must not have any knotholes in the plies and it must use a high-performing, water-resistant glue between the plies. This will ensure that the glue won't stop working even if the wood becomes wet or damp.

Marine plywood is typically used in outdoor furniture and decorative pieces such as benches, gazebos, and planters.

8) Overlaid Plywood

Also called decorative plywood, overlaid plywood is either MDO (medium density) or HDO (high density).

Overlaid plywood has the same plies like other types of plywood such as oak, ash, maple, birch, mahogany, maple, teak, red oak, rosewood, or other hardwoods and is finished on the top with a thin veneer of some ornamental wood.

The overlaid face gives the plywood a finished appearance. Not only does the veneer make the surface look more beautiful, but it also makes it durable and resistant to scratches, water, and other damage.

Typically, the exterior surfaces of the veneers are bonded by a process of pressure and heat. The HDO plywood panels have more resin compared to the MDO panels, which makes them more expensive.

However, both these varieties can make finished projects stronger and more durable compared to traditional plywood.

9) Structural Plywood

Also called sheathing plywood, structural plywood is more for framing strength and permanent building structures. Structural plywood is sturdy and strong; however, it has an unfinished look and is not made with appearances as a concern.

It must be covered by wood or some other material later. Structural plywood requires very strong adhesive that can keep the plies bonded together, and of course it provides this.

While structural plywood may not be as weather resistant as other kinds of plywood, it can still be used either outdoors or indoors for framing, flooring, beams, and bracing panels because it's typically covered with another material.

Usually, structural plywood has C or D grade woods and so it is quite inexpensive; however, it may not have the highest performance required for large outdoor structures.

10) Moisture Resistant Plywood

Also called MR ply or commercial ply, this plywood is used extensively indoors. Right from cabinets to furniture, the plywood is resistant to moisture in humid and damp conditions, making it a great choice in tropical areas. However, MR ply is not waterproof.

11) Boiling Water Resistant (BWR) & Boiling Water Proof (BWP) Plywood

This plywood is commonly used for both interiors, as well as exteriors. The plywood is water resistant, which makes it suitable for all kinds of weather conditions.

It's commonly used in kitchens and bathrooms, where there is a lot of exposure to water. Because of its waterproof nature, the plywood is also used for staircases and exterior wall cladding.

12) Sanded Plywood

In sanded plywood, the face, top, and bottom plies are sanded to make them uniform and smooth. It has a high finish quality and strength-to-weight ratio.

Typically, sanded plywood is used in applications where it's seen by people such as for cabinets, paneling, and shelves. Sanded plywood is also strong and can be used in structural applications.

13) Flexible Plywood

This is usually used for making curved parts, following the practice of furniture making that goes back to the 1850s. It usually comes in at 1/8 inch or 3/8 inch thickness instead of 1/2 inch.

Typically aircraft plywood such as Baltic birch is usually made from 3 or more plies with a 3-ply mahogany bendy board or wiggle board having a very thin central ply of cross grain and 2 exterior plies, either cross grain or long grain.

Once the desired curve is achieved, the wiggle board is glued in two layers, so that the final shape is stiff and resists any movement. Decorative veneers are added often as a surface layer.

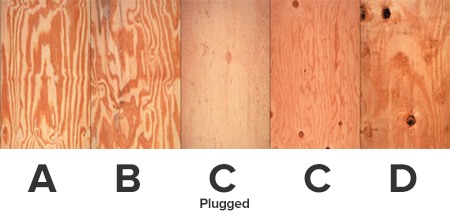

Grades of Plywood

There are four grades of plywood: A, B, C, and D. In that order, they go from the most expensive and visually appealing to the least. You'll occasionally see a grade "C Plugged" where the splits and knotholes are limited in size (1/8th inch width splits and knotholes & 1/4 x 1/2 inch defects otherwise).

A grade will use the highest quality glues with a face and back veneer. D grade will be of the lowest quality wood and glue and won't feature veneer faces and will have the most and largest knots.

Plywood Ratings

Plywood types and grades vary in accordance to their uses. They come in five main ratings, as listed below.

Exterior Rating - These panels are waterproofed, meant to be used for permanent outdoor construction for structures that may face inclement weather.

Exposure 1 Rating - These are also waterproof and can face exposure to the elements, but should not face long-term weather exposure.

Exposure 2 Rating - These panels are not meant for external use as they aren't fully waterproof. They can withstand some exposure to moisture, but not long-term. They're meant for interior building.

Interior Rating - These are only meant to be used indoors and in dry conditions. They should not be exposed to moisture of any type for any length of time.

Structural 1 Rating - These are designed specifically to be resistant to the vibrations and movements caused by earthquakes.

Plywood Plies

A ply, in regards to plywood, is each layer of veneer stacked upon each other. This influences the thickness such that a 5-ply panel is thicker than a 3-ply panel of the same type. This is often the case with the many plywood alternatives too.

3-ply is the most common, typically around 1/10th of an inch thick. It's most often used indoors in more decorative scenarios.

5-ply tends to be around 1/6th to 1/8th of an inch thick and is used indoors and outdoors but not for framing permanent structures.

Multi-ply ranges from 7-ply and upwards. It's strength and durability makes it valuable in framing and roofing of exterior structures.

All Types of Plywood for Various Uses

When selecting plywood for your project, it's extremely important to understand the differences in the various types of plywood as some types are more suitable for certain projects than others. Watching the process of plywood manufacturing is pretty entertaining as well.

Choosing the wrong kind of wood can ruin your work completely (over time, anyways). So now, after reading our article, you'll be able to pick the right types of plywood for your upcoming project.