How to Insulate PEX Pipe Effectively for All Seasons

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

PEX piping is a type of plastic piping that is commonly used in residential and commercial plumbing systems. It's highly flexible and durable, making it a popular choice for many plumbing applications. But we still need to know how to insulate PEX pipe like any other.

Like other types of plumbing systems, PEX pipes require insulation to ensure efficient water flow and reduce energy costs. Learn more about PEX pipe, the advantages and disadvantages of using it, and some tips on how to insulate it for less heat transfer along the water's travels. The result is hotter water and less of a risk of a pipe burst during freezing temperatures.

How to Insulate PEX Pipe

Before we dive into more details about PEX piping, where it originated, and why it’s important to insulate, and the pros and cons of doing so, let’s take a closer look at how to insulate PEX piping. Do you need to insulate PEX pipe? Yes, under certain conditions we explore further below.

Here are the materials you will need for insulating PEX pipe as well as a step-by-step guide on how to do it successfully.

Materials Needed for Insulating PEX Pipe

To properly insulate your PEX piping system, you will need insulation, adhesive tape or caulk, scissors or utility knife, measuring tape or ruler.

What Type of Insulation is Best for PEX Pipe?

For PEX insulation we recommend radiant barrier insulation as the best option. Being made from polyethylene with a tight closed-cell construction helps reduce heat loss to less than 0.9 °F per 100 feet of length as well as other impressive benefits according to studies performed by the Oak Ridge National Laboratory.

This PEX pipe insulation is also flexible like the pipe itself, which will allow you to accommodate bends without gaps in your insulation like you'd experience with foam options.

Use R3 or R4 rated pipe insulation for any pipes exposed to the elements outdoors or in harsher areas like an unfinished basement, attic, or crawl space.

Step by Step Guide to Insulating PEX Pipe

Insulating any types of PEX pipes is a relatively straightforward process. Here are the steps you can take to properly insulate your PEX pipes:

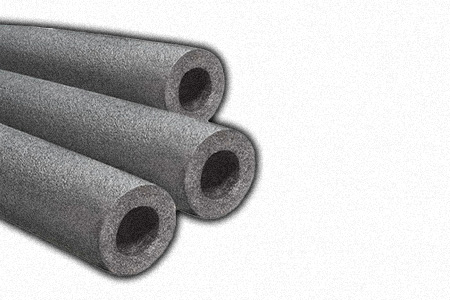

1) Determine the type of insulation you need. There are several types of insulation that can be used to insulate PEX pipe, including foam pipe insulation, fiberglass types of insulation, radiant barrier insulation, and rubber insulation.

Each type has its own advantages and disadvantages, so it's important to choose the type that best meets your needs according to the specific task. Any of these are better than none. Radiant barrier insulation will be the most superior.

2) Measure the length of the pipe you need to insulate. Use a tape measure to determine the length of the PEX pipe you need to insulate.

3) Cut the insulation to the correct length. Use a utility knife or scissors to cut the insulation to the correct length. Be sure to leave some extra insulation at each end to ensure that it covers the entire length of the pipe, especially to account for any bends in the pipe run.

4) Slide the insulation onto the pipe. Carefully slide the insulation over the PEX pipe, making sure that it covers the entire length of the pipe.

5) Secure the insulation in place. Depending on the type of insulation you are using, you may need to secure it in place with tape or adhesive. Follow the manufacturer's instructions for securing the insulation.

Advantages of Insulating PEX Pipe

Insulating PEX pipe has many advantages that make it an ideal choice for a variety of plumbing applications. Insulation helps to reduce energy costs, improve the durability and longevity of the piping system, and protect against freezing in cold weather conditions. Insulation can also provide an opportunity to hide exposed pipes creatively, turning them into part of the decor.

Increased Energy Efficiency

Knowing how to insulate PEX pipe properly and doing so helps to reduce heat loss through the walls of the pipes. This can lead to cost savings by maintaining hotter water for extended durations, thereby decreasing the amount of energy required to keep it at its desired temperature.

Additionally, insulation can help prevent condensation from forming on pipes which can lead to mold growth or other damage caused by moisture buildup.

Improved Durability & Longevity

By insulating PEX pipe, you are protecting it from extreme temperatures that could cause cracking or splitting over time due to thermal expansion and contraction.

The insulation also provides additional protection against corrosion caused by chemicals present in some types of water sources as well as preventing wear-and-tear due to vibration from pumps or other mechanical equipment used with the piping system.

Reduced Risk of Freezing

In areas where temperatures drop below freezing during winter months, insulating PEX pipe is essential in order to prevent freezing which can cause bursting or other serious damage if left unchecked.

The insulation acts as a barrier between outdoor air temperatures and interior liquid temperatures helping maintain consistent internal temperatures regardless of external conditions.

Disadvantages of Not Insulating PEX Pipe

Not insulating PEX pipe can lead to a number of problems. The most common issue is damage from temperature fluctuations.

As the temperature shifts, so does the water inside the tubes; this can cause strain on the pipe setup and lead to splits or breaks in its composition. This can cause stress on the piping system and eventually lead to cracks or breaks in the material.

Additionally, not insulating PEX pipe increases the risk of leaks due to condensation forming on uninsulated pipes during cold weather conditions. This moisture can seep into walls or floors and cause extensive water damage over time if left unchecked.

Another disadvantage of not insulating PEX pipe is that hot water will lose some heat before it reaches its destination when compared with insulated pipes. This is critical in something like a heated outdoor shower where the pipes are exposed to the elements.

Without insulation, heat will escape through uninsulated sections of piping more quickly than those that are insulated, resulting in slower delivery times for hot water throughout your home or business premises.

It is clear that not insulating PEX pipe can lead to costly and dangerous consequences; however, with the right installation techniques and materials, these risks can be minimized. Ultimately, it is evident that the proper implementation of insulation for PEX piping can be essential to avoiding any potential problems.

How to Know Which of Your PEX Pipes Need Insulation

Does PEX need to be insulated? Some runs of pipe will need to be insulated while others won't. There is a "rule of thumb" that can help you determine which pipes need it and which don't, and it's easy to remember and understand.

Rule of Thumb: If a PEX pipe runs outdoors, is in some way exposed to the outside, or runs through an uninsulated area of a home or building, it will need to be insulated.

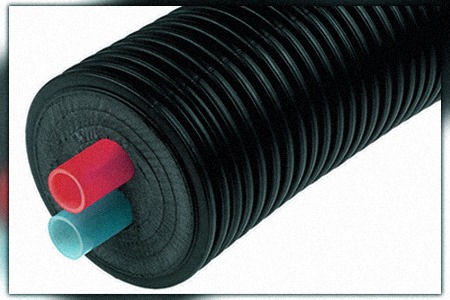

This goes for red PEX, blue Pex, and white or gray when exposed to outdoor temperatures (hot or freezing) and for red hot water lines indoors in uninsulated areas or uninsulated walls. I suggested insulating all hot water lines, regardless, unless they're running through insulated walls. Any pipes exposed to the outdoors should use R3 or R4 pipe insulation.

PEX pipes in rooms with drastic temperature shifts, such as attics, crawl spaces, and basements, can all benefit from insulation. It's relatively inexpensive and not time consuming to do, and the benefits are large enough to warrant the effort. The biggest challenge is simply knowing how to insulate PEX pipe, which isn't hard either.

A Closer Look at PEX Piping

PEX pipe is a type of plastic tubing used for plumbing applications that offer numerous benefits compared to traditional copper and PVC pipes. It consists of cross-linked HDPE molecules fused together at extremely high temperatures, creating an incredibly durable material with superior strength and flexibility compared to other types of piping materials.

PEX pipe offers remarkable longevity, withstanding harsh temperatures without succumbing to the same breakage or cracking that other pipes may experience. Additionally, because it’s so flexible, installation can take less time as fewer fittings are required during installation than what would be needed if using copper or PVC pipes instead.

Furthermore, since there are no joints between sections, leaks are much less likely than they would be with other types of piping systems making them ideal for use in areas prone to freezing temperatures where water damage could occur if not properly insulated against cold weather conditions. PEX piping is also considered more sustainable than competing products.

PEX pipe is a versatile and cost-effective material for plumbing, but proper insulation of the pipes is key to ensuring their longevity.

How Long Have We Been Using PEX Piping?

PEX piping was first developed in the 1960s in Europe as a flexible, durable alternative to traditional copper and steel pipes. However, it wasn't until the 1980s that PEX piping began to gain popularity in the United States.

In 1984, a company called Uponor introduced PEX piping to the U.S. market under the brand name "Wirsbo." The company initially marketed the piping system for use in radiant heating applications, but it quickly gained popularity among builders and plumbers for its flexibility, durability, and ease of installation.

Throughout the 1990s and 2000s, PEX piping continued to gain traction in the U.S. market. It became increasingly popular for use in both residential and commercial plumbing systems, as well as for radiant heating and cooling applications.

Today, PEX piping is used in a wide range of plumbing and HVAC applications and has become a staple of modern construction and renovation projects.

FAQs About Insulating PEX Piping

Check out some of these common asked questions about how to insulate PEX pipe.

What Type of Insulation Should be Used for PEX Piping?

Closed-cell foam insulation is the most commonly used type of insulation for PEX piping. It provides excellent thermal insulation properties and is resistant to moisture, mold, and mildew.

How Is Insulation Applied to PEX Piping?

Insulation is typically applied by wrapping the piping with foam insulation sleeves or tubes. The sleeves or tubes are pre-cut to fit the diameter of the pipe and can be easily installed by slipping them over the piping and securing them in place with adhesive tape or zip ties.

Can PEX Piping be Left Uninsulated?

While it is technically possible to leave PEX piping uninsulated, doing so can result in higher energy costs, as well as increased risk of damage to the piping due to temperature changes or other environmental factors. Insulating PEX piping is a critical step in ensuring the long-term performance and durability of your plumbing system. Buried PEX pipe should still be insulated, too.

What are Some Common Mistakes to Avoid When Insulating PEX Piping?

Some common mistakes to avoid when insulating PEX piping include using the wrong type of insulation, failing to properly seal insulation joints or gaps, and leaving uninsulated sections of piping exposed. It is also important to follow manufacturer instructions and local building codes and regulations when installing insulation.

How Do You Keep PEX Pipes From Freezing?

To prevent PEX pipes from freezing, it is important to ensure that the pipes are properly insulated. This can be done by wrapping them in foam insulation or using a heat tape along their length. Additionally, make sure any exposed piping is covered with an insulating material such as fiberglass wrap or even a blanket.

Finally, keep the temperature inside your home above freezing and consider installing a thermostat controlled heating system if necessary. By following these steps you can help protect your PEX pipes from freezing during cold weather months.

That’s How to Insulate PEX Pipe

Proper insulation can not only improve the efficiency of your plumbing system, but it can also help prevent costly repairs due to damage caused by temperature changes or other environmental factors.

It is essential to select the appropriate type of insulation for your PEX piping system and to follow manufacturer instructions, local building codes, and regulations when installing it. Overall, taking the time to insulate your PEX piping is a wise investment in the longevity and performance of your home's plumbing system. And that's how to insulate PEX pipe effectively.