17 Types of Concrete Blocks for Every Construction Need

Author: Omar Alonso | Editor: Omar Alonso

Review & Research: Jen Worst & Chris Miller

The importance of concrete blocks while constructing buildings, houses, and other structures is second to none. You're probably familiar with brick blocks, but knowing the different types of concrete blocks will work wonders for you in construction.

The advantage of concrete blocks is that they are more tensile compared to bricks, and they are an ideal component in erecting walls and can be used for other purposes.

For a bricklayer, it is crucial to identify the variations of these blocks because there are many different kinds out there, and all have different purposes.

We have come up with this article to highlight the different categories of concrete blocks to facilitate your assembling endeavors.

17 Types of Concrete Blocks

The basics of concrete block are pretty simple, it is made with a mix of water, aggregate, and cement. The cement and aggregate ratio is 1:6 for making concrete blocks though goes as high as 1:9 in the present to maximize their compression strength well over what is required by the construction.

Are all blocks the same in size and shape? Well, this is the difference we want to talk about. Concrete blocks are of two types, one is solid and the other is hollow. An important thing to note is that both these types have subcategories. Let's discuss the groupings below.

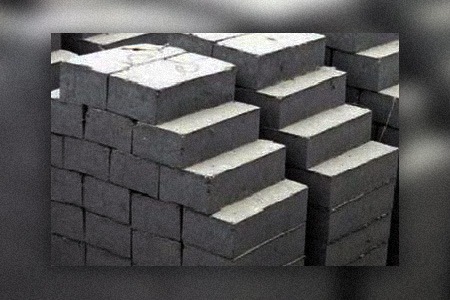

Solid Concrete Blocks

The word solid describes the appearance of the block. It is fully solid and provides strength to the structure. Concrete blocks are used for paving, where the main aim is to build a deck that is rigid and durable. As you can imagine, these cinder block weights are higher than the hollow ones.

These blocks are also used to build walls that need to withstand strong winds. Solid blocks come in different shapes and are heavier compared to hollow ones. There are some common variations of solid blocks, and they serve different purposes.

You've seen these used in many types of sheds and types of house foundations, especially along the bottom of the structure to create a solid and flat surface upon which to build the rest.

Paving Blocks

These are rectangular-shaped boxes used mainly for paving roads and decks where you walk on. These concrete block types are similar to a brick shape, but there are different sizes and shapes available, for example, square ones.

The initial color of these types of pavers varies from light gray, dark brown, sandstone, charcoal, etc. After laying on roads, paving blocks might need to be colored to improve visibility.

Expanded Clay Block

The expanded clay blocks are super-efficient in reducing the load of a structure. These are made with delicate aggregates of cement and fly ash. Clay blocks are also flexible — they can be molded into different shapes while being prepared in a thermally insulated chamber.

Clay, as one of the concrete alternatives, also helps the structure insulate effectively against temperature and sound. The good thing about expanded clay blocks is that they are good at repelling water and fire.

Aerated Autoclaved Concrete Block

The word aerated says it all. These types of concrete blocks are 80% air and therefore very lightweight. Having a somewhat soft end to it, this can be nailed with screws if needed. Keep in mind that AAC blocks are not that strong compared to other solid blocks and are not ideal for load handling.

These different types of cement blocks might need to be customized for use in partitions, sidewalls, and other places. AAC comes in different shapes, like blocks, U-shaped bond beams, panels, etc.

Cellular Lightweight Concrete Block

The cellular lightweight concrete blocks are made with cement, fly ash, and foam. It is very lightweight and also provides good insulation against temperature and sound. Another positive is that these blocks are fire-resistant.

These blocks are used to erect compound walls, parapet walls, and adjoining panels. Another notable feature is that it comes with various densities. High-density blocks are good for load-bearing, whereas low-density ones are for no-load bricklaying jobs.

Fly Ash Blocks

The fly ash blocks are made using fly ash and water, which form a powdery substance acting as pigment to keep things in place. Fly ash blocks are made tough from the get-go. They are resistant to low temperatures and can curb the permeability issue.

Fly ash blocks are generally gray, but the tone can vary depending on the particle color. These particular blocks come in smaller shapes because the bigger it gets, the chances of cracking increase.

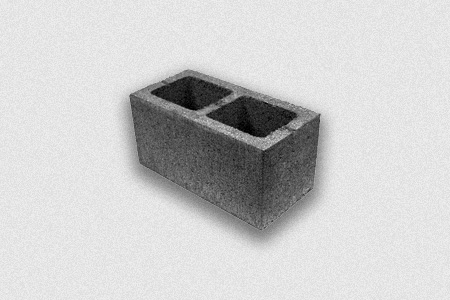

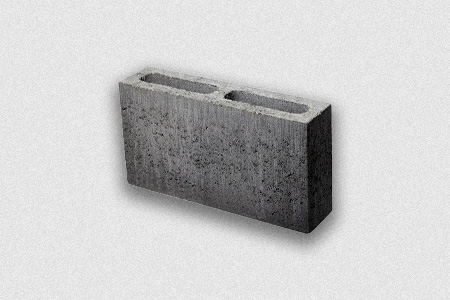

Hollow Concrete Blocks

This particular type has three different grades, which determine the load-bearing functionality. For example grade A (1500 kg/m3 minimum density), grade B (<1500 kgm3) and grade C (> 1000 kg/m3).

Here grade A and B are known to be load-bearing blocks, whereas grade C is a non-load-bearing one. There are many different shapes and sizes of hollow concrete. Let's take a look.

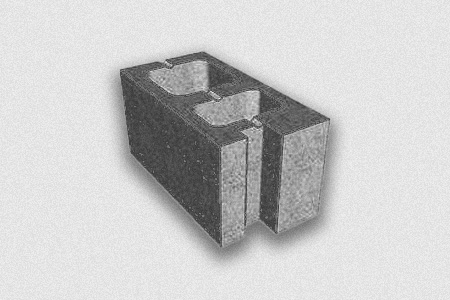

Stretcher Block

For joining corners in the masonry, stretcher concrete block types are the most used concrete blocks in construction plans. These blocks are placed parallel to the wall's face. Beyond special features on their sides for connecting the corners, they look like your standard cinder block.

Pillar Concrete Block

For building pillars, there is no better choice than pillar types of concrete blocks. These blocks are also known as double corner blocks. It is manufactured in a way so that when it is used, the double corners are left uncovered.

When the concrete block comes to mind, many people might opt to name the pillar block at first. These are also used to make piers and are available in vast quantities.

Corner Concrete Block

Just like the name implies, the corner blocks are made to be put on the corners of the masonry. These types of masonry blocks are used mostly on door openings and window corners.

While using it, the stretcher side has to be laid parallel to the face of the wall, and the plain surface is left visible on the exterior end.

Partition Concrete Block

When it comes to partition blocks, the structure has two or three hollow compartments in them. They are almost identical to a pillar box but are much taller. The height of such a block is larger than its breadth. According to its name, you can guess where it is used. Partition walls!

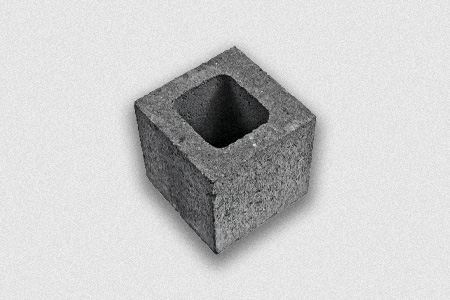

Column Concrete Block

A column block is a square block with a single, square or rectangular hole in the middle. These types of blocks are put one above another to create column designs. Once these types of columns are established one might set a metal rod in the middle to help stabilize the structure.

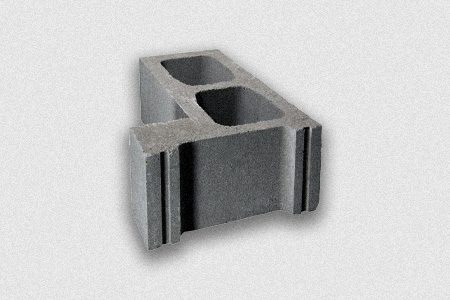

Jamb Concrete Block

These types of blocks are used if there are any extensive window openings on the face of the wall. To make full use of it, jamb blocks are connected to corner blocks and stretcher blocks for proper function.

If there is a double-hung window, then jamb blocks are ideal for providing space for the casing members. The main features are the male and female grooves on either end.

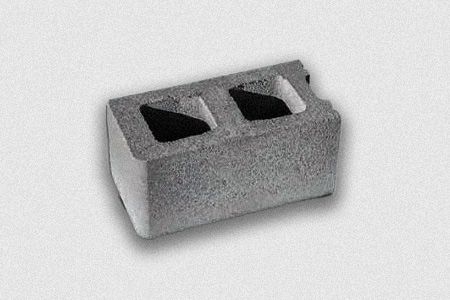

Frogged Brick Block

These blocks have a chamfered hollow part on the top where the mortars are placed in a way so that the brick stays stable and should provide a tougher bonding ability for the overlapping layers.

Split Face Blocks

A split-face block is comparable to pillar types of concrete blocks but has one exception, the textured edge. One of its sides has an overwhelming texture that sometimes highlights the aggravating materials. Frogged face blocks are permeable to water damage but can tackle fire and infestation.

Bullnose Block

The bullnose types of cement blocks are similar to the corner blocks and have similar properties. What separates them from one another is the shaping. In a bullnose block, the edges are round.

These concrete block types can either have one side rounded or both sides curved, depending on your preference, you can purchase the variations. When construction workers need rounded edges on the corner, they will certainly use bullnose blocks to assemble things into place.

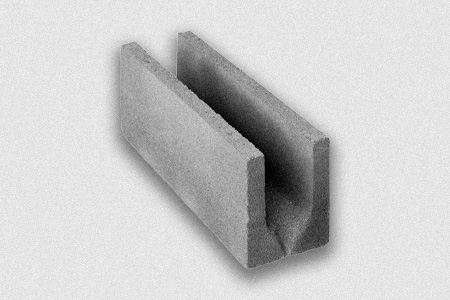

Lintel Concrete Block

A lintel block has a U shape and is also known as a beam block. It is used to construct lintel beams. The groove that goes about the whole length of the block is stacked with reinforced bars and concrete.

Such types of masonry blocks are used on the door and window top to eliminate and handle the load-bearing down. You'll also see these called channeled blocks due to the shape. The channel can be filled with reinforcing bars and then solidified with wet concrete.

Types of Concrete Blocks for Any Structural Needs

Constructing a building can get hectic if you are a bricklayer and don't have extensive knowledge of concrete blocks, especially if you're building a whole cinder block house. You might end up messing things up at your construction site sooner than later.

Therefore, to make things uncomplicated, we have cherry-picked the different types of concrete blocks that are most useful and highlighted their usability in masonry tasks. Look at the contrasting characteristics of the concrete units before planning to put your hands to work.